Business

GF’s lifecycle-driven flow solutions redefine the economics of desalination infrastructure

As water scarcity deepens across arid and coastal regions, desalination has moved from being a technical solution to a strategic pillar of national water security. For governments and utilities, the focus is no longer solely on expanding capacity, but on ensuring long-term economic viability. Infrastructure investments are increasingly assessed on how they perform over decades, rather than at the point of commissioning.

Global estimates show desalination capacity reached almost 97.4 million cubic metres per day in 2023, while production costs have declined to between USD 0.50 and USD 1.00 per cubic metre. This convergence has firmly positioned desalination within mainstream water planning and placed renewed emphasis on lifecycle value.

GF, a global leader in flow solutions, views this shift as a critical turning point in infrastructure decision-making, where durability, efficiency and predictability are now outweighing short-term capital considerations.

Why lifecycle thinking matters in desalination

Desalination plants rank among the most capital-intensive assets in the water sector. Once operational, they are expected to deliver reliable output in harsh environments for 25 years or more. This longevity places sustained pressure on system reliability, maintenance planning and operating expenditure.

GF’s lifecycle-driven approach seeks to optimise flow solutions from the design phase through to long-term operation. Rather than treating piping as a commodity, the company positions it as a strategic system that directly influences energy efficiency, leakage control and asset lifespan.

Piping systems: an overlooked cost driver

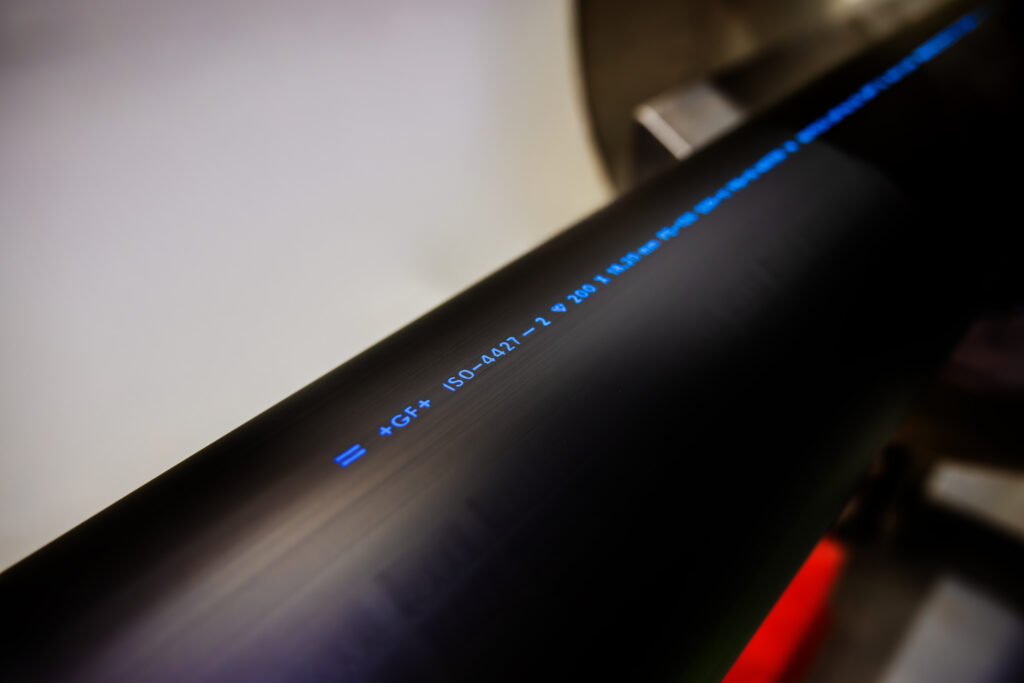

Piping networks often extend for several kilometres across intake, treatment and distribution stages, making their performance central to operational continuity and maintenance budgets. In desalination environments, prolonged exposure to seawater, chemicals, UV radiation and temperature variations can accelerate material degradation if specifications are misjudged.

GF highlights thermoplastic piping systems as a dependable alternative to traditional materials within appropriate pressure and temperature ranges. Their inherent corrosion resistance helps mitigate long-term risk and delivers more predictable performance, a key consideration for operators and investors focused on total cost of ownership.

Leakage prevention safeguards long-term returns

Minor inefficiencies can have significant financial consequences at scale. With production costs approaching USD 1 per cubic metre, leakage rates of only a few percentage points can equate to millions of dollars in lost value over a plant’s lifetime.

GF points to advanced fusion-based jointing technologies, including butt fusion and electrofusion, which create homogeneous, leak-free connections designed to last as long as the pipe itself. These systems enhance long-term reliability while reducing unplanned maintenance and operational downtime.

Driving efficiency through pre-fabrication and standardisation

Labour constraints and project timelines are playing an increasingly influential role in desalination economics. GF promotes pre-fabrication and modular construction as effective strategies to minimise on-site risk, improve quality control and accelerate installation schedules.

Lightweight thermoplastic systems are particularly suited to this approach, enabling complex assemblies to be manufactured in controlled environments before being rapidly installed on site.

Supporting long-term water resilience

As desalination capacity continues to expand across the Middle East and globally, GF believes lifecycle-driven flow solutions will be instrumental in ensuring infrastructure remains reliable, cost-efficient and resilient. For policymakers and investors alike, the ability to predict asset performance over decades is fast becoming as critical as capacity itself.