Ask any scientist that has worked with cell cultures in a lab: contamination is high on their list of fears. Even one stray bacterium or fungal spore can spoil an entire experiment.

Now imagine scaling that risk up to biomanufacturing, which uses living cells to make a range of stuff, including drugs, food ingredients, and industrial materials. There, contamination doesn’t just hamper productivity, it has the potential to harm the public if, for example, bad germs make their way into pharmaceuticals.

Not wanting to take any chances, companies take a scorched earth approach to combating contaminants, blasting their equipment with searing hot steam. But it’s a costly tactic: steam takes a lot of energy to produce, and the equipment has to be hardened against the high temperatures and pressures that occur during sterilization.

“This was an approach developed by Pfizer in the ’40s to make penicillin,” Brian Heligman, co-founder and CEO of Biosphere, told TechCrunch. “And you look at the original systems, they look kind of the same as today.”

Steam isn’t the only way to sterilize equipment. Another is to grow cells in single-use reactors, which is wasteful. Ultraviolet (UV) light is another. Yet until recently, generating enough UV-C light, which is required for decontamination, has been expensive. Now, thanks in part to COVID, they’re a lot cheaper.

“During the Covid era, you saw a lot of capital influx into the manufacture of UV-C LEDs,” Heligman said. “They’ll probably get orders of magnitude cheaper in the next decade.”

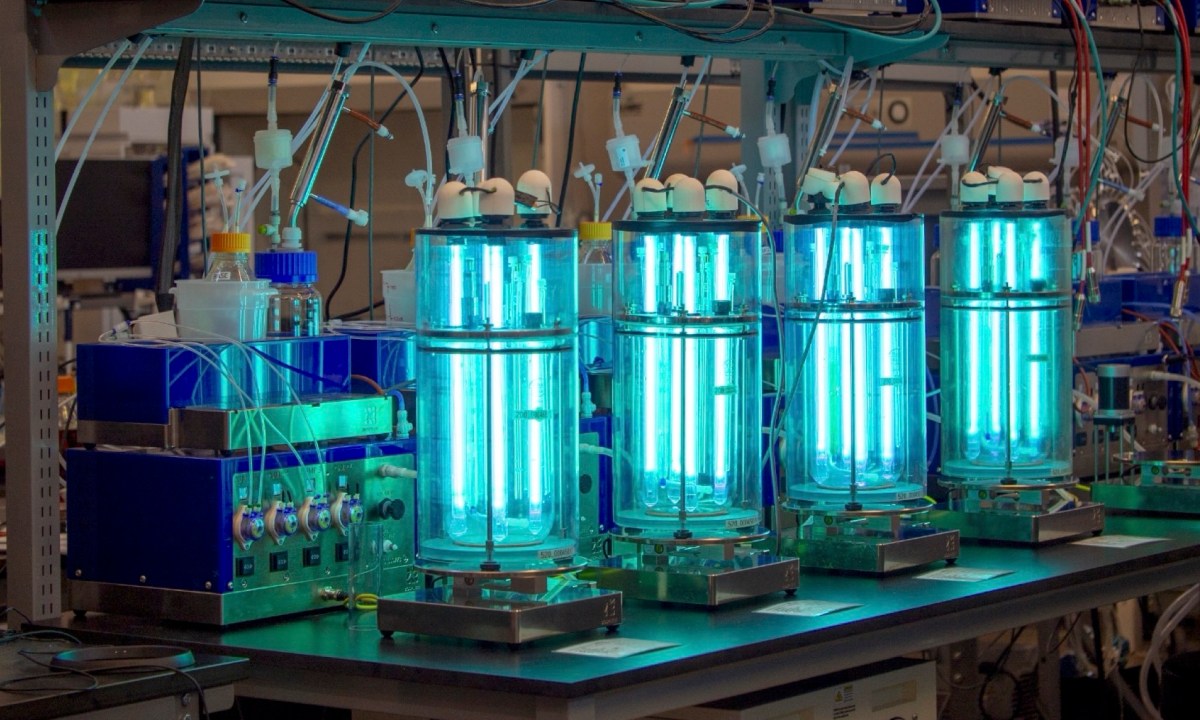

Heligman and his colleagues at Biosphere have spent the last two years designing a three-liter, glass benchtop bioreactor that can be sterilized entirely by UV light. Inside the reactor, four bright LEDs blast every part of the chamber and its instrumentation. The startup is now testing eight of them as part of a $1.5 million Department of Defense project to explore ways to use biomanufacturing to produce high-performance oils.

Using LEDs has the potential to bring down the cost of biomanufacturing, allowing such processes to make materials that previously would have been too expensive.

“As you start to be able to simplify the complexity of these systems, we think we can push to a transformatively lower floor,” Heligman said.

“You can imagine this like an electrification of the bioreactor,” he said, adding that replacing expensive stainless steel valves, traps, and other equipment with LEDs and a cable should help drive costs down significantly. What’s more, because the vessels won’t have to withstand high temperature and pressure, they could be made out of cheaper materials like plastics for certain applications.

The company is currently working to build a pilot bioreactor that can contain around 100 liters and can be sterilized using its technology. After that, Heligman said he’s interested in exploring designs that would be capable of holding 40,000 to 80,000 liters.

Biosphere has raised $8.8 million in seed funding led by Lowercarbon Capital and VXI Capital, the company exclusively told TechCrunch. Participating investors include B37 Ventures, Caffeinated Capital, Founders Fund, and GS Futures.

+ There are no comments

Add yours