This is an audio transcript of the Tech Tonic podcast episode: ‘The geopolitics of chips: Chips in the USA’

Jenny Holton

Most of people are like, more bedrooms. Some people are like, three bedrooms. (overlapping speech)

James Kynge

Real estate agent Jenny Holton is showing me around a bungalow on the outskirts of Phoenix in the US state of Arizona.

Jenny Holton

OK, very popular for them. They like this kind of house.

James Kynge

Holton is Taiwanese-American and she’s just sold this house to a new Taiwanese arrival. She’s been selling a lot of houses like these recently.

Jenny Holton

They always say, oh we watch TV. They do the barbecue in their backyard. They get a yard to . . . for kids to play with, but they buy this kind of style because they want to live American house.

James Kynge

Business is booming for Holton. We step out into the backyard and we can clearly see why. Jenny points into the distance towards a new factory being built by TSMC, the Taiwan Semiconductor Manufacturing Company, maker of the most advanced computer chips in the world.

Jenny Holton

TSMC is right over there, seven minutes from here. Very fast because most people work long hours. So very long hours, they don’t get home maybe eight, nine, 10. So they want to be home rather than wait because they are tired.

James Kynge

Why do they have to work so long?

Jenny Holton

Well, you know, it’s your responsibility to get that things done. That’s what they have been learning all those years in Taiwan. That’s the nature of the job.

James Kynge

The new TSMC factory here in Arizona is part of a US effort to rebuild America’s chip manufacturing industry. And there’s a lot riding on its success, not least America’s ability to stay ahead of China in the global race for tech supremacy. It’s a rivalry sharpened by China’s incendiary claim that TSMC’s home turf of Taiwan is part of its own territory. But it turns out that recreating Taiwan’s world-beating chip production in the heart of America is, well, complicated.

In this episode, America’s dream of bringing chipmaking back home.

[MUSIC PLAYING]

This is Tech Tonic from the Financial Times. I’m James Kynge, a longtime China correspondent to the FT. There’s a battle going on for control of the global semiconductor industry. The chips that are in virtually every piece of electronics we use, from our phones to our cars to the latest AI software that’s changing our lives. For the past half century, chips have powered the technological revolution. In this series, I’m going deep into the miracle of modern chip manufacturing and the struggle over who controls the industry’s future.

[MUSIC PLAYING]

One of America’s main strategies to bring semiconductor manufacturing back to the US is called the Chips Act. It pledges tens of billions of dollars in taxpayer-funded subsidies. And the idea is to persuade semiconductor companies, including TSMC, to make chips in America. But the initiative is now facing political turbulence. The Chips Act was passed by President Joe Biden, and now Donald Trump is heading to the White House.

Donald Trump voice clip

That chip deal is so bad.

James Kynge

That’s an extract of an interview Trump did with the popular Joe Rogan Experience podcast in October. It’s not that Trump doesn’t want to bring manufacturing back to the US. He clearly does. What he objects to is taxpayers’ money being used to do it. Instead, Trump says putting tariffs on chip imports to the US would force those chip companies to relocate to US soil.

Donald Trump voice clip

To me, the most beautiful word — I’ve said this for the last couple of weeks — in the dictionary today and any is the word tariff. It’s more beautiful than love, more beautiful than anything.

James Kynge

And he lashed out at Taiwan, in particular.

Donald Trump voice clip

Taiwan, they stole our chip business. They want us to protect and they want protection. They don’t pay us money for the protection.

James Kynge

It’s hard to know how seriously to take Trump’s remarks on the Chips Act. We just don’t know to what extent they will be implemented after he becomes president. But to understand the current geopolitical maelstrom, we have to reach back a little into America’s industrial past right here in Phoenix, Arizona. There was a time long ago when the global semiconductor industry was centred in America, with chips being manufactured in this corner of the American south-west.

We’re standing on a parking lot next to a main road in Phoenix, and it’s blazing hot, the temperatures over 100F. We’re looking for the site of the Motorola factory that used to make semiconductors dating way back to 1949. That was the first semiconductor manufacturer here in Phoenix, Arizona. We’re now trying to find where it used to be, but there’s not much here apart from a car park and a flowerbed with desert flowers and cactus in it. There’s a big area of like of sand and concrete. Could it be over there, maybe?

Today, there’s not much left of Motorola’s chipmaking glory here in Arizona.

This site apparently is what’s called a Superfund site, which means that it’s toxic underneath. And so that seems to be the legacy of Phoenix’s first semiconductor factory.

Motorola closed its site in Arizona for good in the early 2000s as most of America’s chipmaking was offshored to Asia. But now, Washington wants to bring it back to US soil.

Eric Schmidt

In hindsight, the right people in national security should have said, you know, we’re going to want to have this kind of leading edge capability in the United States.

James Kynge

Eric Schmidt is a former chairman and CEO of Google. And these days, he advises the US government and the tech industry. Schmidt was influential in the drafting of the Chips Act. He’s currently chair of a Washington think-tank called the Special Competitive Studies Project.

Eric Schmidt

One of the important historical decisions was that in the 90s, the US let those industries — which were invented largely in the US — go initially to Europe, but especially to Asia, starting in Singapore and in other places like that. And I can tell you when I was doing this, it didn’t occur to me that this was that important. I figured that it was sort of a commodity like everything else. I’m sure the Asians would do well and our future was in software. And I think it’s only recently that America has come to understand the importance of having our own domestic chip manufacturing.

James Kynge

So today, the US is playing catch-up. This is important because chips are absolutely crucial for new technologies, for economic growth and for national security. But the way chips are being manufactured today is very different to America’s chipmaking heyday.

Eric Schmidt

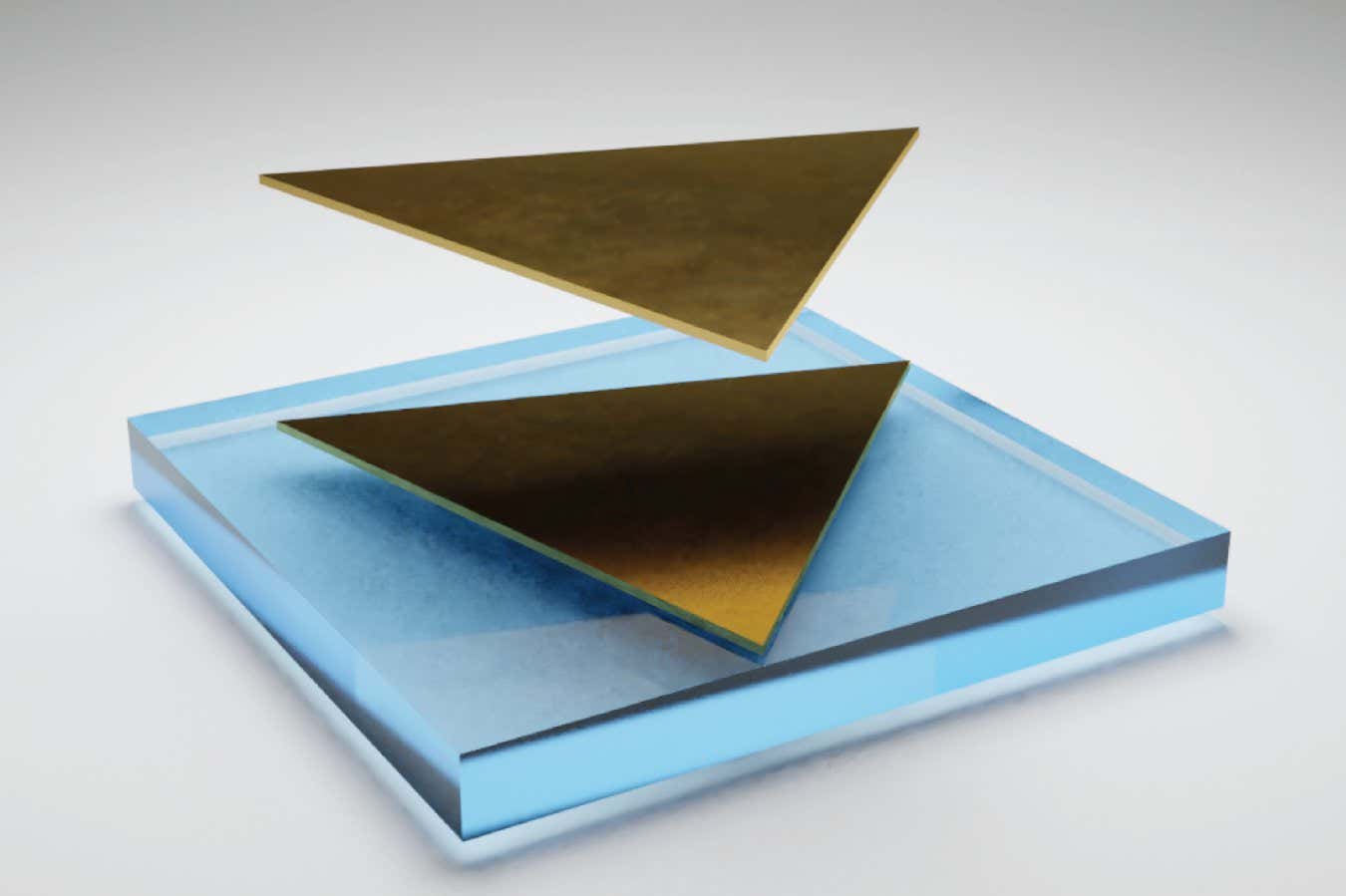

During that time, the fabs and the architectures were completely integrated. So in other words, the semiconductor buildings, the supply, the photolithography machines and so forth were all vertically integrated with the designers.

James Kynge

Several decades ago, the industry began a shift towards what’s called the foundry model. American companies sold their manufacturing businesses and focused on designing chips rather than making them. And they sent the manufacturing to foundries overseas, which make all sorts of chips on a contract basis for companies like Apple and Nvidia.

Eric Schmidt

And the key decision that was made, which was essentially the split where you had foundries that worked in secret with specific companies and they didn’t leak the technology from one to the other. They were highly, highly intellectual property protected. It was a model that would give the foundries scale.

James Kynge

With that scale, the foundry model thrived in Asia, where labour was cheap. And the company that really won out was TSMC. To be clear, TSMC doesn’t design its own chips. Instead, it makes other people’s chips in its fabrication sites or fabs as they’re known. TSMC has benefited from massive Taiwanese state support, and today the US is trying to replicate Taiwan’s success with the Chips Act.

Rose Castanares

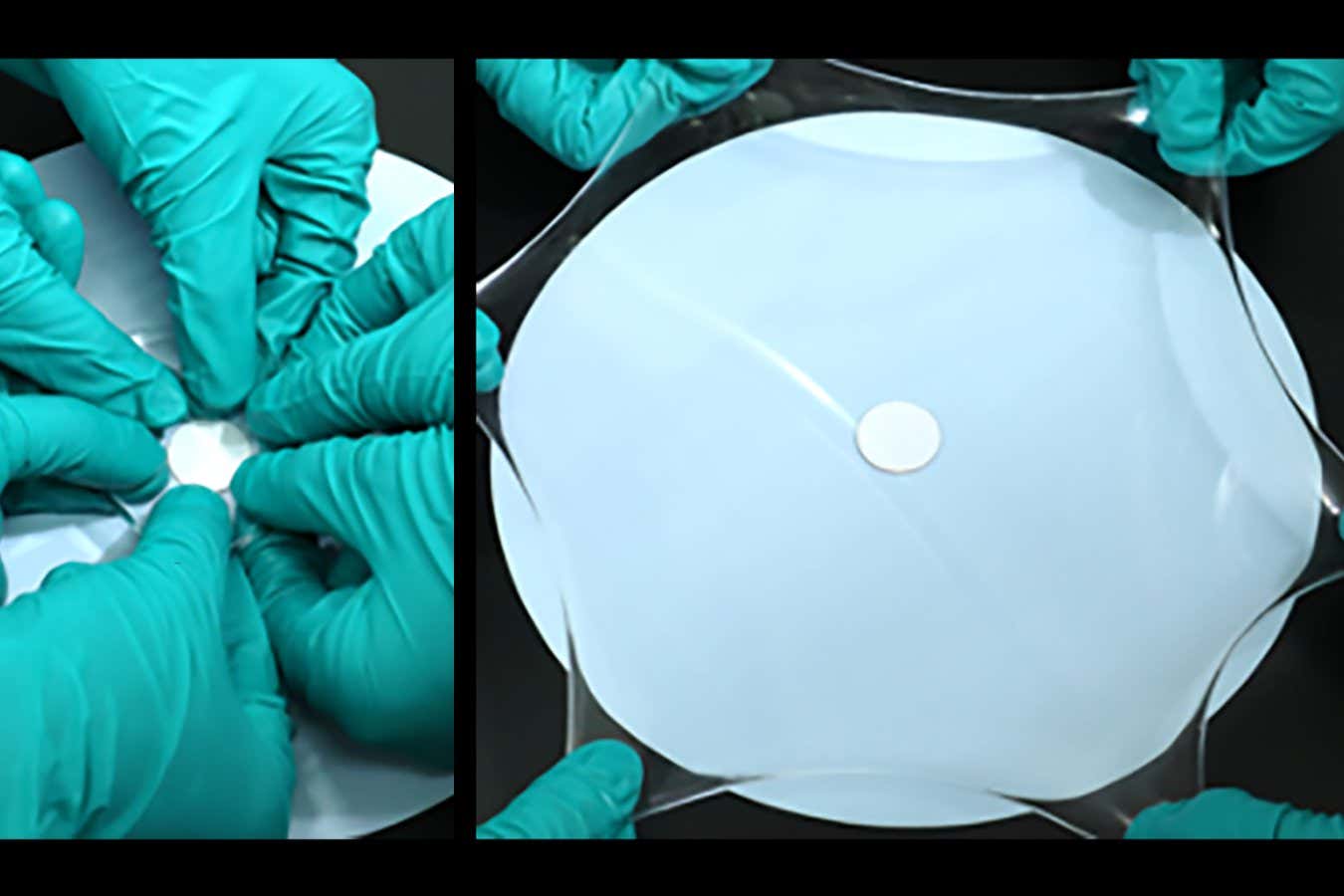

We’re standing on the north side of the gown building. We call it the gown building because this is where our workers in the clean room get gowned up. It’s been called bunny suits. They’re very cute.

James Kynge

Rose Castanares is head of TSMC Arizona. TSMC’s factory is still under construction, but the bunny suits are already being worn. We’re standing outside a gleaming glass structure that’s risen out of the dusty desert landscape. Workers are streaming by and new buildings are being raised around us.

Rose Castanares

You might want to try our boba tea shop.

James Kynge

Oh, you got a boba tea shop?

Rose Castanares

We’ve got a boba tea shop. Yes, and I . . .

James Kynge

What, here? In the factory?

Rose Castanares

In here. Right across from the Starbucks.

James Kynge

Surrounded by nothing but cactus and desert scrub, the factory stands like a mirage in the desert. A mirage that even sells Taiwanese bubble tea. This TSMC factory is the largest foreign greenfield investment in US history.

Rose Castanares

We’re scheduled to be in production in first half of 2025. We are running wafers to be able to make sure that the quality is good, that the yield is good before we go into full production.

James Kynge

When it’s complete, this factory will be making chips that are close to the cutting edge, putting the US generations ahead of its rival China. But some doubts linger over TSMC’s longer-term commitment, particularly in light of a Trump presidency. The plan is for six phases of development at this site. But TSMC has so far only committed to three.

Rose Castanares

The Chips Act was $6.6bn and our initial investment for Fab 1 and Fab 2 was $40bn. Then we increase that to three fabs for a total of 65. So, you know, you can say that without the US government wanting us to be here and helping us, we wouldn’t be here. The money itself is a fraction of what we need to be able to run the fab. It certainly helps.

James Kynge

So US government money helps. But Castanares says that’s not the full picture.

Rose Castanares

We had a major customer that requested that TSMC build in the United States and we took that into consideration. We also asked our other customers if they felt like they wanted us to be here.

James Kynge

TSMC wouldn’t tell us which customers had asked them to set up shop in Phoenix. But you might be able to take a guess from who attended a recent ceremony at the factory.

Tim Cook voice clip

As many of you know, we worked with TSMC to manufacture the chips that help power our products all over the world.

James Kynge

That’s Apple chief executive Tim Cook speaking at the ceremony.

Tim Cook voice clip

And we look forward to expanding this work in the years to come as TSMC forms new and deeper roots in America.

James Kynge

But putting down deeper roots in America is no easy feat. Costs in the US are much higher than they are in Taiwan. That hits TSMC’s bottom line. The level of consumer demand for these expensive chips may end up dictating whether TSMC builds further capacity in Phoenix.

When we asked them about the election results, TSMC said, and I quote: The most important factor in our decision to expand in the US was consumer demand, adding that they were committed to their Arizona investment, an investment which in any case had actually been agreed during President Trump’s first term.

[MUSIC PLAYING]

But there’s another issue that might pose a problem for the company: a skills gap in the United States. Where is TSMC going to find all the specialised technicians it needs to operate this plant? This problem already caused a delay in the building of the factory last year.

Rose Castanares

The delay was . . . it was really just a matter of experience and there were so many firsts. We have been building fabs in Taiwan for many years. So, you know, very . . . they’re very used to it. And there has not been an advanced semiconductor fab built in the US for a long time.

James Kynge

All of which explains why TSMC is bringing over skilled engineers from Taiwan. Another expense that the company will have to contend with. Perhaps ex-Google CEO Schmidt, who we heard from earlier, put it best.

Tim Cook voice clip

It’s much harder than people think. In Taiwan when they get a physics PhD and they put them in one of the semiconductor fabs, the first thing that that physicist does is they work the night shift managing the machines. Can you imagine doing that to American physicists? Another example is that if you look at the experience in TSMC in Arizona, the labour costs, the permitting costs — and this is with the most willing state and federal guarantees — have resulted in costs that are multiple times higher than the cost in Taiwan.

James Kynge

Making semiconductors requires the most sophisticated manufacturing industry in the world. And it’s not just about bringing the Taiwanese over to Arizona. The United States will also need to figure out how it can build up its homegrown chip industry.

[MUSIC PLAYING]

The US is trying to revive its homegrown semiconductor manufacturing industry. President Biden’s Chips Act offered lavish funding and policy support. It’s been enough to tempt TSMC to America’s shores. But now, incoming President Trump has signalled that he’d be willing to tear up the Chips Act and use tariffs to strong-arm companies into setting up in the United States. Regardless of what policy lever is used, if America wants to produce the best chips, it will need a large, highly skilled workforce.

Kevin Reinhart

We have to have you put boots on.

James Kynge

Kevin Reinhart is executive director in research management at the Arizona State University, or ASU. It runs a state-of-the art training site for the chip industry.

Kevin Reinhart

Now, there’s a secret to this. Sit down.

James Kynge

Thank you, yes.

We put on some protective gear and Kevin showed us around the facility. We’re looking through a kind of wire mesh window here at the full clean room, and it’s bathed in the kind of rather mysterious-looking orange light. Lots of machines there, vents in the floor, vents in the ceiling so that the air can circulate, extremely clean air. The losses that are incurred if a single speck of dust gets into those wafers is enormous.

Kevin Reinhart

What you’re standing on is a raised floor that ends up being a 3ft raised floor. So all of your gas piping, chilled water, all that stuff is under floor. So there’s all this infrastructure that’s built around that clean space so that you don’t have particulates on it.

James Kynge

Running a clean room like this is expensive. And the actual process for making semiconductors can be dizzyingly complicated. So working at a chip fab requires a highly specialised skill set and ASU’s job is to quickly train up a new generation of American workers who’ll appeal to the likes of TSMC.

Kevin Reinhart

It’s an all-of-nation approach. We’re certainly doing what we can, and I think from the workforce development site, they want these students coming out and immediately be able to make an impact. The estimates today are like takes 18 months for a student once they’re out of college before they’re fully up and running in a fab environment.

James Kynge

That’s pretty good. You can train up a lot.

Kevin Reinhart

We’re trying to speed that up. So the faster you’re productive, the better your profit margins are, the more you’re competitive.

James Kynge

Looking at the numbers, it’s clear why the industry is pushing for faster turnarounds. At ASU, there are currently about 7,000 students enrolled across semiconductor-related engineering programs. But the US is expected to need about 100,000 new chip workers over the next five years.

The American efforts to resuscitate the chipmaking industry isn’t just about bringing over Asian companies. The US wants American companies to start making more advanced chips again as well. Companies like Intel. Intel used to be a big chipmaker and it wants to scale up its production once more.

We’re doing a four-part series on semiconductors generally. Is that a barking in the background?

Bruce Andrews

It is. And let me go put my dog in the basement.

James Kynge

OK.

James Kynge

Bruce Andrews is corporate vice-president at Intel.

Bruce Andrews

Hold on one second, OK? (Inaudible) Let’s go to the basement. Come on. Basement. Let’s go.

James Kynge

He was at home in DC when I spoke to him via video link. But Intel also has a long history in Phoenix. They’ve had facilities there since the 1980s and are currently expanding their Arizona site, thanks to the Chips Act. There was a period when Intel supplied virtually all of the chips for the personal computer market, but its business started to flounder after it missed out on a deal to supply chips for Apple’s iPhone.

Bruce Andrews

There’s no sugarcoating that several years ago, we stumbled and allowed ourselves to fall behind. You know, Intel had basically been responsible for every major innovation in the semiconductor industry for 50 years. But we did allow ourselves to fall behind several years ago.

James Kynge

Several years ago is when Intel made the decision to expand back into the foundry business, manufacturing chips for other companies, just like TSMC does. But more recently, Intel has struggled to make that business profitable. They’ve now tied their fortunes to a new chip, the 18A, which they say will be able to compete with those from TSMC.

Bruce Andrews

We feel actually very good about where we are with what we call 18A, which is a sub new 2nm technology. We’re very excited about that and we think that it will both bring us back to technological leadership, but also allow us to make the most advanced chips in an Intel fab.

James Kynge

Intel is set to receive billions in Chips Act funding, which could be a real lifeline for the company. But that money hasn’t actually been dispensed by the government yet, and Trump’s second term could put that funding at risk. On the other hand, Intel could actually benefit from a Trump presidency’s focus on American self-sufficiency.

Bruce Andrews

The US needs Intel to be successful, both from the standpoint of having a US manufacturing option, but also for the resiliency of supply chains and building up the US industry.

[MUSIC PLAYING]

James Kynge

Back in Phoenix, real estate agent Jenny Holton is feeling the weight of expectations. She took me on a drive around the gated community where she’s been selling homes to Taiwanese chip engineers.

Do you think this whole move to bring TSMC over here for America to reshore its semiconductor industry, do you think that’s going to work out?

Jenny Holton

Everybody wants it to work out. Everybody would do their best to make it work out. But there are a lot of factors in play. Waiting is looking good.

James Kynge

So Jenny is hopeful that TSMC will expand here. She also said there’s another reason that people want TSMC to move manufacturing capacity to the US.

So what’s your feeling about China? You know, the rivalry with America. Does that scare you or concern you at all?

Jenny Holton

It does concern me a bit. Some people think China might invade Taiwan. My family are in Taiwan. They are worried about that as well. So, well, lots of people that come here they might think of as a great opportunity because they get a chance to live a different life. They may be able to stay here long term. It’s very beneficial for them.

James Kynge

We’ll discuss the vulnerability of Taiwan to an attack from China later in this series. But for now, former Google chief executive Eric Schmidt, who you heard from earlier, says subsidies may be the only way to build up a robust American semiconductor industry.

Eric Schmidt

You have to be globally competitive on cost or it has to be a subsidy out of the American taxpayer. It looks to me like we can’t be globally competitive. It will therefore require a subsidy from the American taxpayer. You can think of the Chips Act, the 50bn or so as essentially that subsidy. It’s an example where America must spend a higher fee, if you will, a security fee.

James Kynge

But whether it’s the carrot of Biden’s subsidies or the stick of Trump’s tariffs, the question of chip reshoring isn’t going anywhere. The next superpower will be a tech superpower. And to be that superpower, you need the most advanced chip industry in the world.

I remember a contact telling me to think of it as the Manhattan Project of our time. That project was undertaken during world war 2. The aim was to produce the world’s first nuclear weapons. It’s a slightly alarming analogy, but it gives a sense of how pivotal this chip project is to the security and prosperity of the US, particularly as it competes with China for global tech supremacy.

[MUSIC PLAYING]

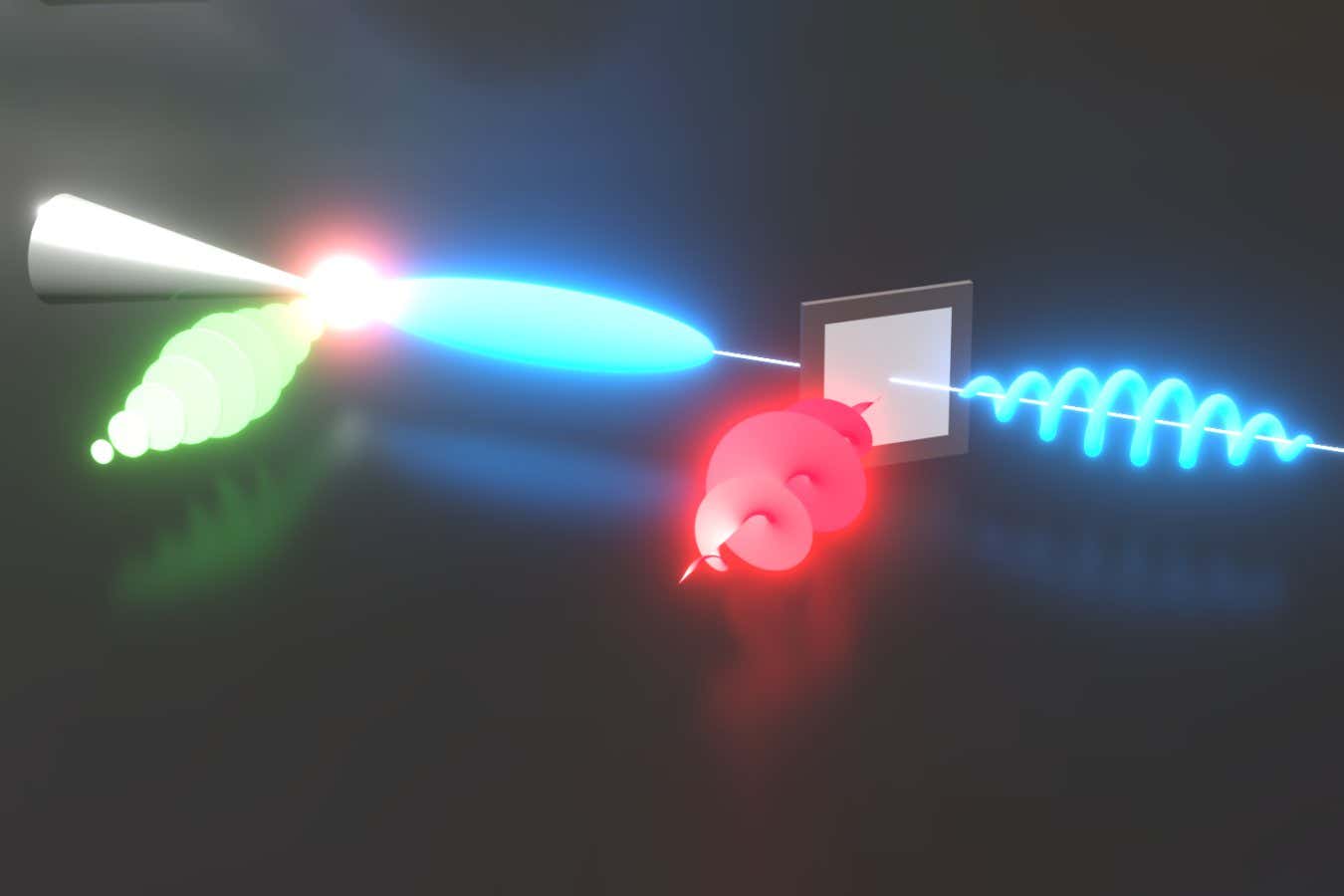

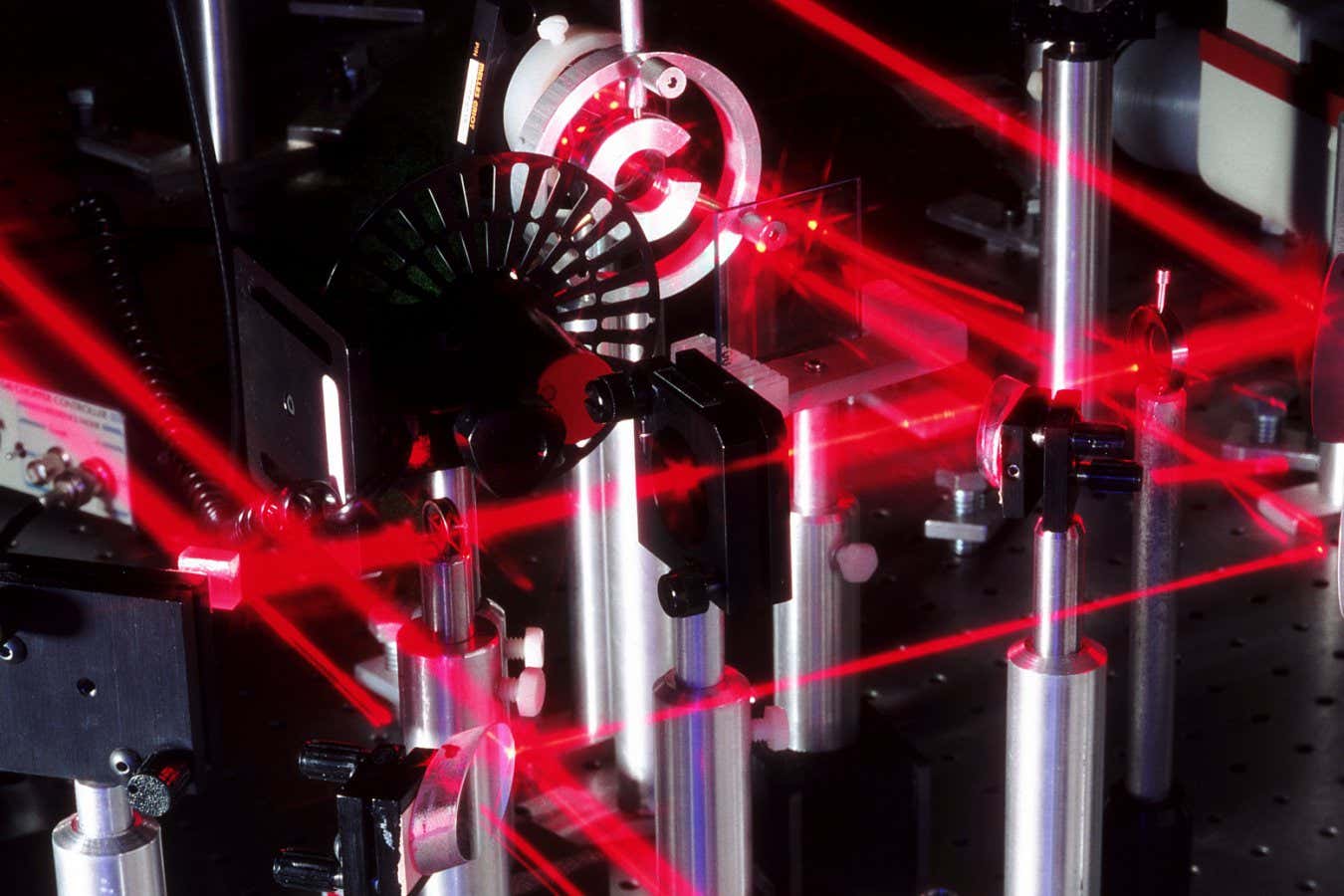

In the next episode, we go deeper into the scientific and technological miracle of modern chipmaking.

Unnamed speaker

This is the entire machine. So this is essentially the most advanced chipmaking machine in the world.

James Kynge

It’s absolutely huge. I find out how Moore’s Law has shaped the global chip industry, putting it at the centre of US-China tech rivalry.

Unnamed speaker 2

If you can’t produce cutting-edge chips or at least something very, very close, your ability to develop expensive products or to train cutting-edge AI systems is going to be extraordinarily limited. And so the US and its allies are betting that they’ll be able to stay meaningfully ahead of China.

James Kynge

Tech Tonic is presented by me, James Kynge. Our senior producer is Edwin Lane and our producer is Josh Gabert-Doyon. Executive producer is Manuela Saragosa. Sound design by Breen Turner and Sam Giovinco. Music by Metaphor Music. Our global head of audio is Cheryl Brumley.

[MUSIC PLAYING]

You must be logged in to post a comment Login