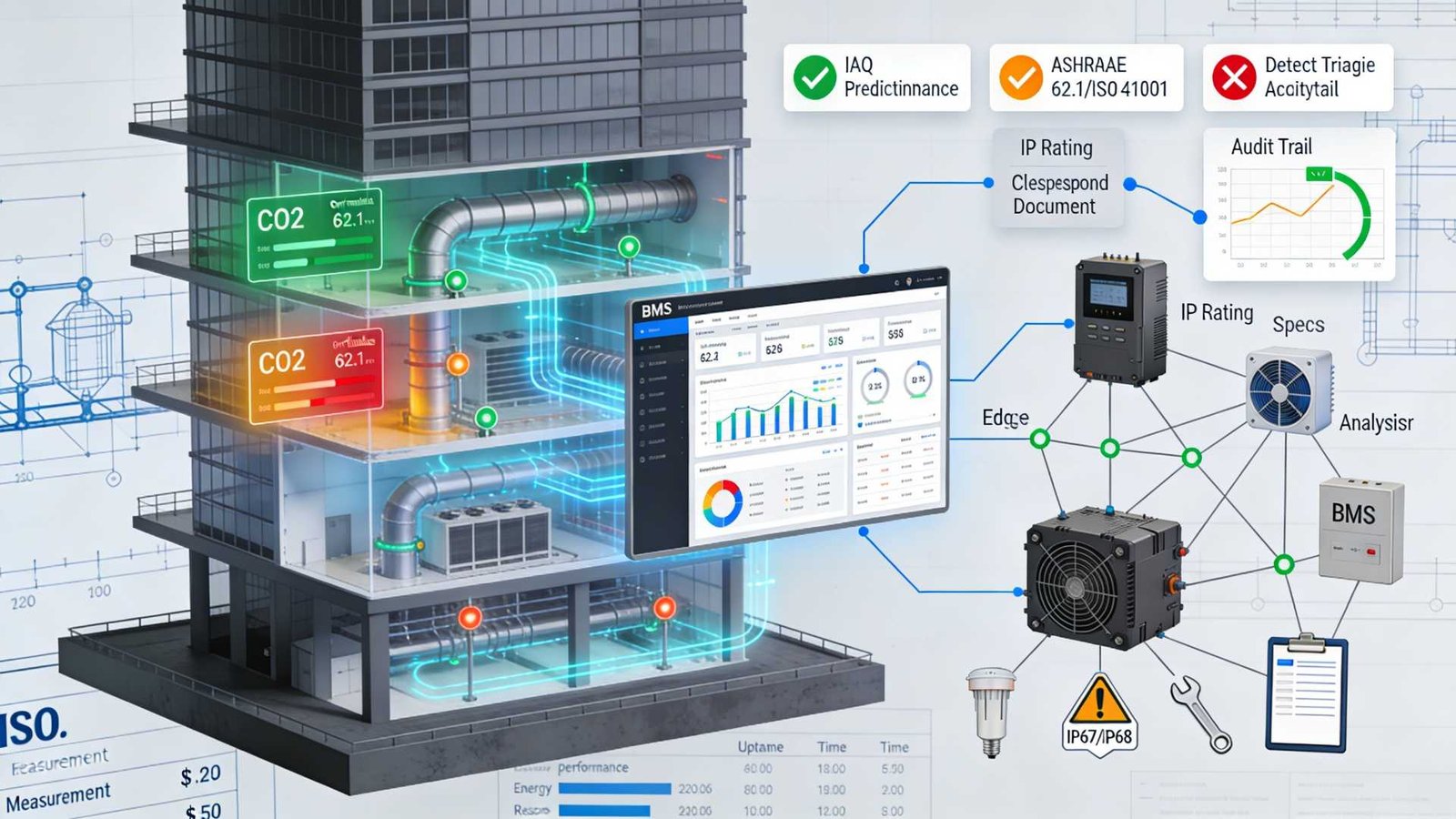

Advanced monitoring is becoming standard because modern facilities are judged on outcomes—air quality, uptime, safety, energy performance, and documented response—not on whether a checklist was completed last week. Ventilation and indoor air quality expectations are formalised through recognised standards, and newer editions increasingly emphasise controls, performance, and operations, which push organisations toward measurable, continuous data.

The changing risk profile (visibility is now a liability issue)

Facilities today are dense systems: people, HVAC, access control, OT/IoT, and vendors. The risk surface includes invisible variables (CO₂/ventilation adequacy, particulates, VOCs, temperature/humidity excursions) and failure modes that don’t announce themselves during routine walkthroughs.

ISO 41001 frames facilities management as a management system aimed at the effective and efficient delivery of FM, supporting organisational objectives and consistently meeting stakeholder and applicable requirements—language that aligns naturally with continuous measurement and documented processes.

Summary: Risk shifted from “obvious hazards” to “system behaviour,” and system behaviour requires instrumentation.

Real-time data is an operational requirement (not a dashboard hobby)

Real-time monitoring creates a new operating model: detect → triage → respond → document. That shift matters because it reduces the time between anomaly and action, and it creates auditable records of conditions and responses (useful for regulated sectors and insurer scrutiny).

Where standards are explicit about ventilation and IAQ, the operational burden increases. ASHRAE notes that 62.1/62.2 are recognised standards for ventilation and acceptable indoor air quality, and the 2025 edition highlights additional requirements and control sequences (e.g., demand-controlled ventilation control sequences, emergency control requirements, humidity control requirements).

Summary: Once you’re accountable for continuous conditions, periodic checks no longer scale.

Hardware built for harsh environments (define “rugged” with specs)

In industrial/institutional settings, monitoring often fails at the edges: vibration, dust, washdown, temperature swings, and physical impact. “Rugged computers” should mean measurable environmental tolerance—especially ingress protection.

IEC 60529 defines IP ratings with two digits: the first (0–6) indicates resistance to solid objects/dust, and the second (0–9) indicates resistance to liquids. In practice, this lets you specify hardware for the environment (e.g., dust-heavy warehouses vs washdown production areas) rather than buying consumer mini-PCs and hoping.

When NOT to ruggedise: If the device lives in a conditioned IT closet, you may be paying for durability you don’t need; invest instead in redundancy, power protection, and serviceability.

Summary: Reliability is a system property, and edge hardware specs are part of reliability engineering.

Environmental monitoring beyond compliance (IAQ as performance)

Facilities increasingly monitor more than temperature/humidity: CO₂ as a ventilation proxy, particulates, VOCs, and noise exposure. The point isn’t “more sensors”—it’s closed-loop improvement: correlate excursions with occupancy, HVAC modes, and outcomes (complaints, absenteeism, equipment faults), then adjust operations.

This aligns with how ASHRAE describes 62.1/62.2 as ventilation/IAQ standards and emphasizes updated requirements around filtration, controls, air cleaning, and operations/maintenance—areas where continuous sensing provides feedback rather than guesswork.

Summary: Environmental data is only valuable when it feeds decisions, not when it fills storage.

Integration with BMS (monitoring becomes control)

Monitoring is most valuable when integrated with building management systems (BMS) and incident response workflows. Without integration, you get alerts; with integration, you get controlled response: ventilation adjustments, escalations, and unified incident records.

A practical architecture pattern:

- Sensors (IAQ/asset/environment) → edge gateway → secure message bus

- Analytics/rules engine → ticketing/CMMS + BMS actions (where appropriate)

- Audit layer → immutable logs, retention policy, reporting

Summary: Standalone monitoring is reporting; integrated monitoring is operations.

Behavioural monitoring and policy enforcement (high value, high governance)

Behavioural detection (e.g., vape detectors) can reduce blind spots in low-visibility areas, but it introduces governance requirements: clear purpose, minimisation, retention limits, access controls, and documented response rules.

If you deploy behavioural monitoring, treat it like a policy-controlled safety system—not a surveillance toy. The technical bar should include false-positive management, tamper detection, and a defensible incident workflow.

When NOT to deploy: If you can’t articulate “what action follows an alert” and who is authorised to act, you’ll create noise, distrust, and compliance risk.

Summary: Behavioural monitoring is powerful—but only when paired with governance.

Data-driven maintenance (condition-based beats calendar-based)

Predictive maintenance is the economic engine behind monitoring adoption. If you can detect drift (fan performance, vibration anomalies, temperature rise, runtime patterns) you shift maintenance from “fixed schedule” to “based on condition,” reducing unnecessary work and preventing downtime.

Tie maintenance analytics to:

- Asset criticality tiers (what must never fail)

- SLAs (response time, uptime)

- Parts lead time risk

Summary: Monitoring becomes standard when it pays for itself via avoided downtime and targeted labour.

Compliance, documentation, and liability reduction (the audit trail is the product)

Standards-driven environments reward documented control. ISO 41001 emphasises consistently meeting the needs of interested parties and applicable requirements, which is easier to demonstrate when you have objective records of conditions, alerts, and responses.

The defensible story looks like:

- “Here were the thresholds.”

- “Here were the readings.”

- “Here were the alerts.”

- “Here’s what we did, and when.”

Summary: In modern facilities, data isn’t just insight—it’s proof.

FAQ

What’s the difference between monitoring and a BMS?

Monitoring and alerts: A BMS can control building systems. Value increases when monitoring is integrated into BMS workflows, so data becomes action.

Do we need rugged computers for monitoring?

Only where the environment requires it, IEC 60529 IP ratings define dust/water resistance with two digits, helping you specify equipment for harsh conditions.

What standards are pushing facilities toward continuous IAQ visibility?

ASHRAE 62.1/62.2 are recognised standards for ventilation and acceptable indoor air quality, and the 2025 edition highlights additional requirements around controls and operations that benefit from continuous data.

How does ISO 41001 relate to monitoring?

ISO 41001 defines requirements for an FM management system to deliver FM effectively/efficiently and consistently meet stakeholder/applicable requirements, which aligns with measurable monitoring and documented response.

Key takeaways

- Advanced monitoring is becoming standard because compliance and accountability increasingly require measurable outcomes and documented control.

- Rugged edge hardware should be specified according to environmental standards such as IEC 60529 IP ratings, not by vague marketing claims.

- The real leap happens when monitoring integrates with operations (BMS + maintenance workflows) and produces audit-ready records.