Technology

Ex-SpaceX engineers land $14M to scale new method for 3D printing metal

3D printing objects using metal is a well-established technique, but it tends to be too complex, expensive, or imprecise to match traditional methods at scale. Armed with $14 million from Nvidia and Boeing, Freeform aims to change that by building a new metal additive printing process that it says changes the game — and yes, there’s an AI angle, too.

Co-founders Erik Palitsch (CEO) and TJ Ronacher (president) both worked at SpaceX, where they were principal architect and lead analyst, respectively, of the Merlin engines and other programs. While there, they saw the potential of 3D printing parts using metal, but also experienced the method’s shortcomings firsthand.

“We saw the potential of metal printing; it has the potential to transform basically any industry that makes metal things. But adoption has been slow and success has been marginal at best,” said Palitsch. “Why is it not practical to use at scale? Fundamentally, because of three things: crappy and inconsistent quality; speed — commercial printers are very slow; and cost — the price for these printers is astronomical.”

They concluded that if they could operationalize the process to provide a printing service rather than sell a printer, they could crack the whole thing wide open. So they joined up with Tasso Lappas, former CTO of Velo3D, to start Freeform.

The primary mistake companies were making was using the likes of CNC machines, which are commonly used in traditional manufacturing, as a model for the metal-printing business. In that case, you sell the machine and its software, and make it work with whatever shapes and processes you use. But metal additive is different, Palitsch said.

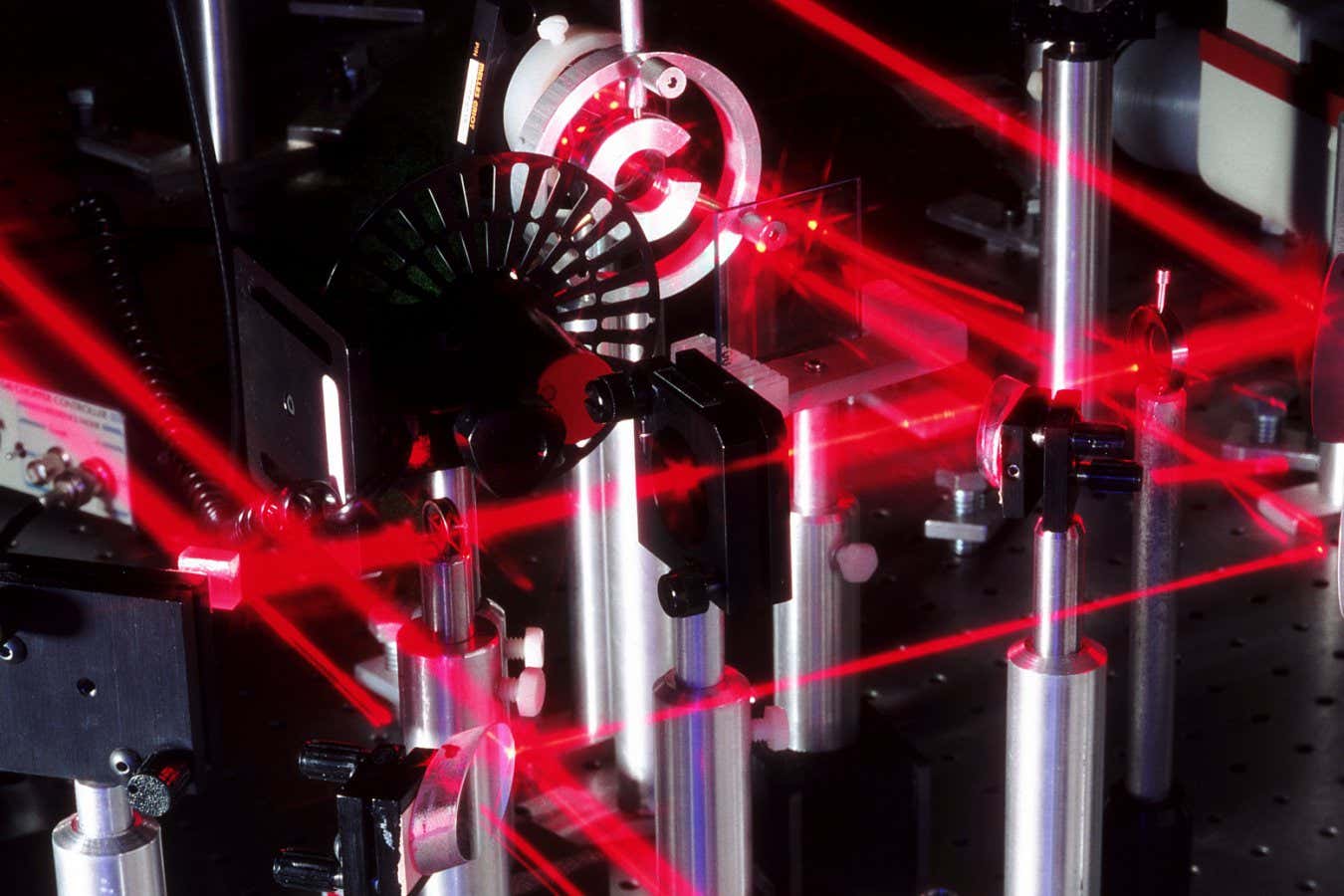

“The way these things work today is they’re ‘open loop’ — they’re basically playing back a file,” he explained. “They needed to be smarter than that, because the process by which you melt metal powder with a laser is extremely complicated, and in a way infinitely variable.”

Selling people a machine and saying “become an expert to make it work, good luck,” isn’t a recipe for success.

“But when you decide you’re not going to build and package a printer into a box, when you have the freedom to build an automated factory from clean sheet, there’s a lot you can do,” Palitsch said.

Their solution is to provide printing as a service using a closed-loop process in a custom machine that monitors the print on a microsecond scale, adjusting various factors to achieve the kind of print that is expected at a workplace like SpaceX.

The company has plenty of tech advances to boast of, but the two most immediately relevant are the feedback loop and the AI that manages it.

“We have high-speed computer vision feedback on our system that runs at microsecond scale, and all that data is being processed on state of the art FPGAs and GPUs. We had to build this whole stack ourselves out of stuff that’s only become available in the last few years,” said Palitsch.

The closed-loop system with real-time monitoring mitigates the quality issues while still allowing speedy printing of complex geometries. And by operating as a printing service, they keep the business model simple.

But making that part of the system work required the second tech breakthrough: a machine-learning model fast enough and expert enough to actually perform that monitoring.

“Erik and TJ lived this and reached the same conclusions, that this industry required a level of compute and sensors that no one had ever deployed before,” said Lappas.

“To properly understand how to control the process, we needed datasets working at timescales that no one had. So we started building a state of the art telemetry system, a platform that would collect curated, controlled, almost self-labeled datasets.”

This data allowed them to bootstrap a model to generate more data for a better model, and so on.

But then they ran into the necessity of speed.

“There’s a lot we have in common with generative models, and a lot we don’t. But one thing that’s absolutely different is the latency,” Lappas explained. “Our inference needs to happen in microseconds so that we can close the loop on these processes.” With no off-the-shelf solution available for the data or the compute, they had to build the GPU/FPGA “AI on steroids” combo from scratch.

A consequential side effect: Freeform is “building the largest metal additive dataset in the world — that’s why companies like Boeing are coming to us,” said Palitsch. “We have this fundamental, core data collection and processing ability no one else has.”

Add that to the fundamental benefits of printing-based manufacturing, like the agility and versatility of factories, and it makes a pretty compelling business case.

Boeing’s AE Ventures and Nvidia invested a total of $14 million, though they declined to break that down further. Each company’s investment comes with perks: Nvidia gives them access to H100s and other compute hardware, while Boeing will shepherd them through the supplier qualification process and likely buy a bunch of parts. (Freeform will also join Nvidia’s Inception startup program.)

Palitsch said they have customers in the aerospace, automotive, industrial, and energy sectors, “the whole nine.” They declined to put any on the record, but did mention they’re making everything from rocket engine components to exhaust parts for Formula 1 cars. They plan to use the money to scale up, build out their next generation of (much faster) printers, and hire up to around 55 people total over the next year.

He admitted that their approach has taken time to grow from theory to reality, but that their methodical, technical approach is also what enabled their success.

“It was a slow transition,” Palitch said. “But I look back at it… with six people, we built, from scratch, the fastest laser melting platform on the planet, and the hardware and software for it. We did things people said you couldn’t do.”

Technology

Why SPADEX is crucial to India’s growing space ambitions- The Week

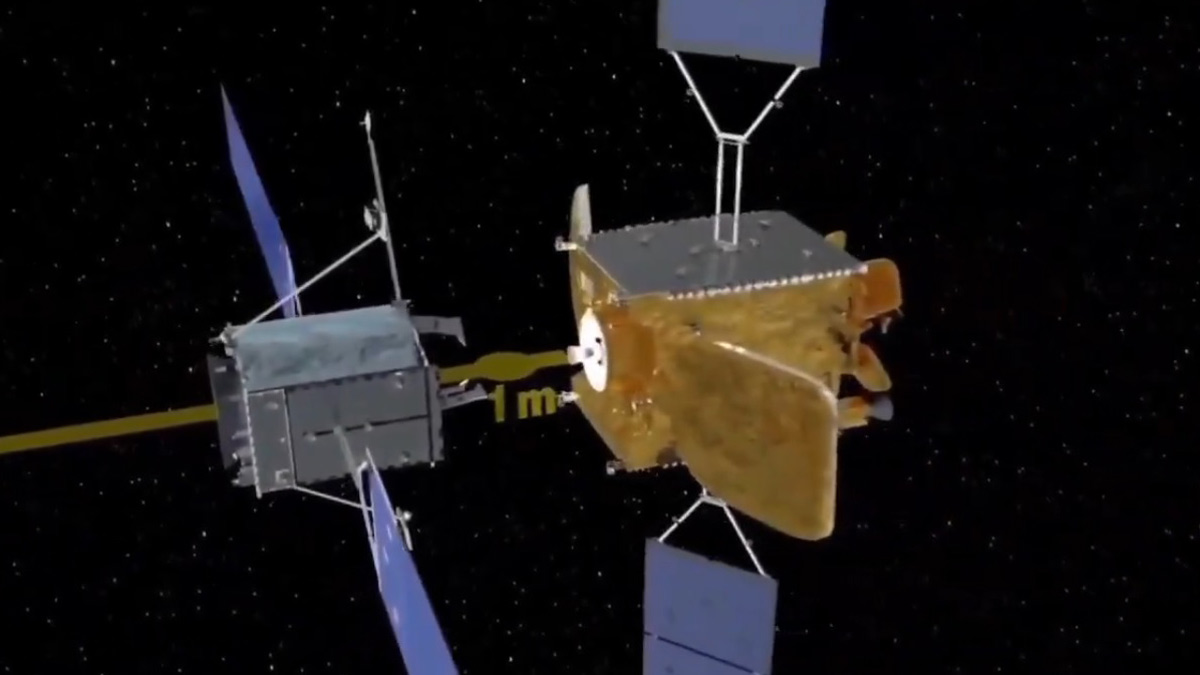

SPADEX (Space Docking Experiment) is one of ISRO’s most significant steps towards developing autonomous docking technology, crucial for India’s growing space ambitions. Docking systems allow two spacecraft to connect in orbit, enabling critical operations like assembling space stations, refueling, or transferring astronauts and cargo. SPADEX is key to achieving India’s long-term space exploration goals, including manned spaceflight, satellite maintenance, and future space station construction.

The mission involves two vehicles—‘Chaser’ and the ‘Target’—coming together and connecting in space. It will also test how well the combined spacecraft maintains stability and control after docking, ensuring smooth operations for future missions.

Once docked, the two spacecraft will later separate to perform additional tasks. This experiment is crucial for ISRO to develop the skills needed for advanced missions, such as human spaceflight and lunar sample returns. Mastering these docking and rendezvous techniques is essential for the success of such ambitious operations.

Hyderabad-headquartered Ananth Technologies, an aerospace and defence company, successfully completed the satellite integration project for ISRO. This also marks a private player joining the SPADEX Mission. Ananth Technologies Private Limited (ATL) successfully assembled two 400 kg satellites for ISRO and delivered them to the UR Rao Satellite Centre (URSC) in Bengaluru. This centre is responsible for designing and developing satellites for various space missions. “We have been manufacturing electronic subsystems for ISRO since 2000 and have been an integral part of every Indian space programme over the last two decades,” Subba Rao Pavuluri, chairman of ATL, said.

ALSO READ: Why ISRO’s involvement in ESA’s PROBA-3 mission is a milestone

ISRO usually builds its satellites at the URSC. However, for the first time, the complete assembly, integration and testing of satellites have been handled by an Indian private company at a private facility. This change is possible thanks to the recent space sector reforms, which provide more opportunities for private companies to participate in India’s space missions. Since the satellites have arrived at the URSC, they will soon be transported by truck to the Indian Spaceport in Sriharikota. There, they will undergo further testing, be fuelled, and be prepared for launch in the coming months.

“Docking plays a vital role in managing space stations and undertaking complex space projects. Astronauts travelling to a space station depend on precise docking to connect their spacecraft safely, allowing them to transfer smoothly between vehicles. This process ensures a secure journey and helps complete missions successfully, whether the astronauts remain in space or return to Earth,” remarked space expert Girish Linganna.

He said when two satellites approach each other at speeds of around 8 kilometres per second, they must coordinate carefully to avoid a collision. Using cameras or lasers, the lead satellite slows down to allow the trailing one to catch up smoothly. Once aligned, the two satellites connect to form a larger system. These precise connections enable more complex operations and allow multiple components to function together, expanding what can be achieved in space beyond the limits of a single satellite.

“In addition to supporting human spaceflight, docking is critical for constructing larger space structures. By connecting different spacecraft and modules, docking makes it possible to build advanced facilities in orbit and expand space exploration. Without these techniques, large-scale space projects would not be feasible,” added Linganna.

READ MORE: Ananth Technologies successfully completes satellite integration project for ISRO

ISRO has acquired two satellites, each weighing 400 kg, for a SPADEX mission. In this mission, a single rocket will launch both satellites into space, placing them in slightly different orbits. This setup is essential to test how well the satellites can approach, align and dock with each other in orbit, demonstrating key technologies for future missions.

The two satellites, travelling at about 28,000 km/h (or around 8 km per second), will carefully align with each other to perform a ‘space handshake’, where they will connect and attach mechanically, becoming a single unit in orbit. This experiment is important because mastering docking is essential for future missions, such as Chandrayaan-4 and India’s proposed Bharatiya Antariksha Space Station.

The history of docking systems dates back to the Cold War when the Soviet Union achieved the first successful docking in space. On October 30, 1967, the Soviets completed the historic docking of Kosmos 186 and *Kosmos 188—the first fully automated docking between two unmanned spacecraft. This paved the way for later space exploration efforts, including long-term stays aboard space stations. The United States followed this with the Apollo-Soyuz Test Project in 1975, which was the first international docking between NASA and the Soviet space agency, marking a new era of cooperation despite ongoing geopolitical tensions.

Docking technology has evolved considerably since then. Early systems required significant manual input from astronauts, but advances in automation have changed this dramatically. Russia’s Soyuz and Progress spacecraft, which service the ISS, have highly reliable automated docking systems. NASA’s Commercial Crew Program, which relies on spacecraft like SpaceX’s Crew Dragon, also uses automated systems, often with the International Docking System Standard (IDSS) for compatibility across different space missions. China, too, has developed its Tianzhou cargo spacecraft, which docks autonomously with the Tiangong space station, showcasing its growing sophistication in space operations.

“India’s SPADEX experiment is unique because it focuses on developing indigenous, scalable, and cost-effective docking technology. This experiment involves two spacecraft docking autonomously in orbit, demonstrating precision, navigation, and control capabilities critical for future missions. SPADEX is designed to serve a wide range of spacecraft sizes and mission objectives, including potential collaborations for building space stations or deep space exploration,” remarked Srimathy Kesan, founder and CEO of Space Kidz India, which is into design, fabrication and launch of small satellites, spacecraft and ground systems.

India is advancing in space exploration at an accelerated pace. ISRO’s recent successes, such as the Chandrayaan-3 mission, which made a soft landing on the Moon’s south pole, and the launch of Aditya-L1 to study the Sun, demonstrate the agency’s capabilities. “SPADEX aligns with these achievements, reinforcing ISRO’s long-term vision for space exploration, especially as the Gaganyaan mission approaches. Gaganyaan, India’s first manned mission scheduled for 2025, will require docking technology to ensure safe crew transfer and module operations. SPADEX is integral to this, as autonomous docking will be essential for future crewed missions, satellite servicing, and space station operations,” said Kesan.

Technology

Horizon developers are “done” with Killzone

Guerrilla Games has been working on the Horizon series for years, and it shows no signs of slowing down, which is bad news for fans of Killzone, its initial franchise. In a new interview, a Guerrilla developer said the studio was “done” with the hyper-dark shooter series when it pivoted to making Horizon Zero Dawn.

“We were done with it as a team. As a studio, we needed to refresh the palette. It was, by choice, the opposite of Killzone,” art director Roy Postma told The Washington Post.

Guerrilla Games officially began making games in 2003, and its first big hit was Killzone, a dystopian sci-fi first-person shooter. It went on to make five Killzone games in total, with four developed after Sony purchased the developer. However, when it pivoted to making Horizon, it left Killzone behind, capping off the series with Killzone: Shadow Fall in 2013.

There haven’t been many mentions of Killzone from publisher Sony Interactive Entertainment, either. There were three Killzone cameos in Astro Bot, which pulled characters from all of PlayStation history, but that’s about it. Servers for Killzone: Mercenary on PlayStation Vita were shut down in 2020.

The studio didn’t go too much lighter in tone with Horizon Zero Dawn, but it’s going down the family-friendly route with its next release, Lego Horizon Adventures, on November 14. It’s a retelling of Horizon Zero Dawn, but with blocky characters, a more playful sense of humor, and simplified gameplay. In a preview at Summer Game Fest, we found it had a “childlike charm” that can help parents share the series with their kids. The team is also releasing Horizon Zero Dawn Remastered on October 31. Recent reports also claim that Guerrilla is working on “Horizon online” ahead of a third mainline game.

Don’t expect any Killzone news from Guerrilla, but who knows, maybe with the recent trend of remasters and remakes (Legacy of Kain: Soul Reaver 1 & 2 Remastered is coming to consoles on December 10, as one example), we can see something from another studio.

Technology

Audeze’s Maxwell gaming headset comes in a spicy new color

Audeze has announced a new version of its Maxwell wireless gaming headset with the Wasabi Edition. It’s a “spicy” new flavor that as the name suggests, displays brilliant green and yellow hues that shift when looking at the headset from different angles.

The Audeze Maxwell is one of the top gaming headsets on the market, and it’s become one of our favorites after having tested it over the last several weeks. The headset normally comes in one color outside of these limited edition variants. A sleek gunmetal gray with a matte finish. The Wasabi Edition comes in a glossy finish for a more eye-catching look, especially with how bright the colors are.

The iridescent green/yellow design, while new, follows the same style as Audeze’s previous limited edition Maxwell headset that came in Ultraviolet. Much like that headset that came out last year, the Wasabi Edition is only available in limited quantities. It was released today, and Audeze still appears to have stock available too. The fact that it’s limited though likely means the stock won’t be available for too long. You are paying a little bit of a premium for this model as opposed to the standard color as well. However, the price increase isn’t drastic.

The Maxwell Wasabi Edition retails for $329, whereas the standard model is $299. So you’re only looking at $30 more.

The Audeze Maxwell Wasabi Edition is compatible with Xbox, PC, and mobile

It’s important to point this out since the headset lists Xbox, PC, and mobile as the only compatible platforms. However, the Wasabi Edition should work just fine with PS5. Several users with the standard Xbox model have claimed that it works on PS5 and there’s no reason it shouldn’t. After all, it uses a USB-C low-latency adapter for the connection. So all you need to do is plug that in. That being said, the Wasabi Edition was designed in partnership with Microsoft for Xbox.

All that really means is that it’s part of Microsoft’s Shimmer campaign for officially licensed Xbox accessories. And that it can take advantage of the Dolby Atmos spatial audio that Xbox offers.

There are no differences between this and the standard edition

Other than the color, of course. Outside of the color though the headset is completely the same. Audeze has confirmed this. So if you don’t care for the green and yellow iridescent color, you aren’t missing out on any features. With that said, the Wasabi Edition gets the same great ANC and immersive audio capabilities as the other models. The detachable mic is the same as well. So, it may look different, but it will sound just as good as the other Maxwell versions. No worse, no better.

It is more flashy, and that makes it perfect for anyone who enjoys a little color with their gaming peripherals. You can only buy this directly from Audeze while supplies last.

Technology

Reltio update delivers new AI-powered matching capabilities

The latest Reltio platform update advances the vendor’s AI capabilities beyond natural language processing to include its core data unification capabilities.

Like many data management and analytics vendors, Reltio developed an AI-powered assistant that enables users to work with their data using natural language rather than code. Reltio Intelligent Assistant was included in an early 2024 platform update and is similar to tools from peers such as Informatica.

Reltio’s new update, launched on Oct. 21, includes the general availability of FERN, which is an acronym for Flexible Entity Resolution Networks. FERN is an AI-powered data matching engine built using pre-trained large language models (LLMs) and is designed to enable users to match customer data so they can develop a more complete view of each customer.

In addition to FERN, Reltio’s platform update is highlighted by new automated customer segmentation capabilities in Customer 360 Data Product, which is Reltio’s AI-powered platform for customer data.

With its focus on AI and automation to reduce time-consuming tasks and make users more efficient, Reltio’s update is significant for customers, according to Doug Henschen, an analyst at Constellation Research.

“Reltio is pushing AI innovation in this release with both dynamic segmentation and the FERN customer data matching engine,” he said. “In both cases it’s using AI to be more responsive to changing business conditions while also augmenting humans by eliminating tedious manual work steps.”

Based in Redwood City, Calif., Reltio is a master data management vendor whose platform is geared toward helping customer unify their data. In addition to Informatica, competitors include specialists such as Semarchy and Stibo Systems as well as more broad-based vendors including Boomi, SAP and Tibco.

In June, the vendor’s platform update included prebuilt master data management capabilities with industry-specific tools and, like its October update, features aiming to improve segmentation. More recently, in August, Reltio unveiled an integration with Collibra designed to help joint customers better discover and govern data assets across different organizational domains.

Platform update

Data from a single customer can be difficult to match to develop a complete profile and tailor sales and marketing efforts to best appeal to that customer.

With customers sometimes having multiple accounts, sometimes using a middle initial or abbreviating a street address but not doing so other times, and multiple members of a household with accounts, , it can be close to impossible to discover all data about a single customer considering that enterprises collect billions of data points.

Matching data is therefore onerous for humans, a painstaking process that consumes copious a lot of time. And given how difficult it can be to match data, even after hours of effort, customer profiles could be missing plenty of potentially valuable data. Even rule-based matching that automates customer profiling misses data that could be used to better inform personalized marketing efforts.

FERN is designed to solve customer matching problems, saving potentially hundreds of hours of work and improving matching accuracy.

The new Reltio tool is prebuilt, meaning no model training is required on the part of the user, and uses LLMs and machine learning-based matching capabilities that discover, define and configure customer data so it can be integrated to form a complete customer view.

In addition to FERN, Reltio’s update features improved AI-powered audience segmentation capabilities in Reltio Customer 360 including segments that evolve based on customer behaviors and needs such as purchases, claims and call center interactions. The segmentation capabilities are aimed at enabling users to better develop audience segments that improve customer experience, retention and growth.

“Dynamic segmentation and the FERN customer data matching engine both stand out,” Henschen said. “In both cases what’s promised is faster, better results.”

Beyond the AI-powered capabilities, Reltio’s update addresses data security and data governance.

The new security features are aimed at strengthening security for core enterprise data. Reltio already offer single sign on and client-credential verification. Now, it is adding multi-factor authentication. Regarding data governance, a new integration with Microsoft Purview Data Governance is designed to simplify discovery of trusted data assets for reuse and help organizations develop data products that can be shared across the enterprise to inform decisions and actions.

Regarding the impetus for developing the new features in Reltio’s latest update, Venki Subramanian, the vendor’s senior vice president of product management, said it came from a mix of customer feedback and observing market trends.

For example, FERN resulted from Reltio’s own observations about the power of LLMs and the growing need for tools that improve efficiency while the integration with Microsoft Purview Data Governance — and recent integration with Collibra — was driven by conversations with customers.

“Ultimately, our mission is continually innovating and providing capabilities that help our customers stay ahead of the curve,” Subramanian said.

Looking ahead

With Reltio’s latest update now available, the vendor plans to continue focusing on the combination of data unification and AI by adding capabilities that enable customers to build their own AI-powered features fueled by trusted, unified data, according to Subramanian.

In addition, akin to its integrations with data governance platforms, the vendor’s roadmap includes adding more integrations that enable its users to develop a data management and analytics ecosystem with Reltio at its core, Subramanian continued.

“Our focus remains on delivering a high-performance, enterprise-grade platform that supports all business-critical operations,” he said.

Henschen, meanwhile, said that Reltio’s recent focus on delivering AI-powered capabilities has given it a competitive advantage over some of its peers — at least in the present, given the pace of AI innovation and how quickly vendors are now pumping out AI-powered capabilities.

With not only FERN and Customer 360 Data Product but also Reltio Intelligent Assistant, the vendor has launched tools that use AI to make its users more efficient and potentially more profitable. And it’s doing so at a pace faster than competitors such as Informatica that have a broader data management focus and thus tend not to innovate as quickly in niches such as master data management and customer 360 specialists, according to Henschen.

“I see Reltio as a master data management-focused innovator,” he said. “There are other innovative MDM-focused vendors … but with these announcements, Reltio seems to be raising the bar — for now at least — on AI innovation.”

Eric Avidon is a senior news writer for TechTarget Editorial and a journalist with more than 25 years of experience. He covers analytics and data management.

Servers computers

Locking Rack Drawers | RDL Series

🎵 For new product features, tips & tricks, breaking news and more, join the conversation:

• http://www.instagram.com/onstagestands/

• http://www.facebook.com/OnStage.Stands/

• http://twitter.com/onstagestands

• http://www.on-stage.com

🎵 A proud brand of The Music People, Inc. for over 40 years:

• http://www.themusicpeopleinc.com .

source

Servers computers

Server Rack with secure locking door. 19-inch Quality Server Racks by Lehmann IT. Made in Germany.

We are known as an innovative, competent manufacturer of server and network cabinet systems for secure and efficient IT infrastructures and as a reliable supplier to the IT and electronics industry.

IT-Infrastructre Solutions:

Economical and secure solutions for small and medium server rooms, room-in-room solutions such as IT security cells, and up to larger data centers are no problem for us. The innovative product range covers classic racks, enclosures based on the cold aisle-hot aisle principle, intelligent PDUs and UPS systems, in-line cooling units, side cooling units, direct rack cooling for high packing densities, and refrigeration, free cooling, edge computing, and much more.

Silent Solutions:

As a specialty, we offer unique solutions for noise reduction of IT hardware in sensitive environments, wherever noisy IT hardware is to be operated in offices, conferences, and training rooms. With the Silent Solutions brand, Lehmann has soundproofed 19″ cabinets and enclosures in various designs in its program.

https://www.lehmann-it.de/en/

#shorts #serverrack #servercabinet .

source

-

Science & Environment1 month ago

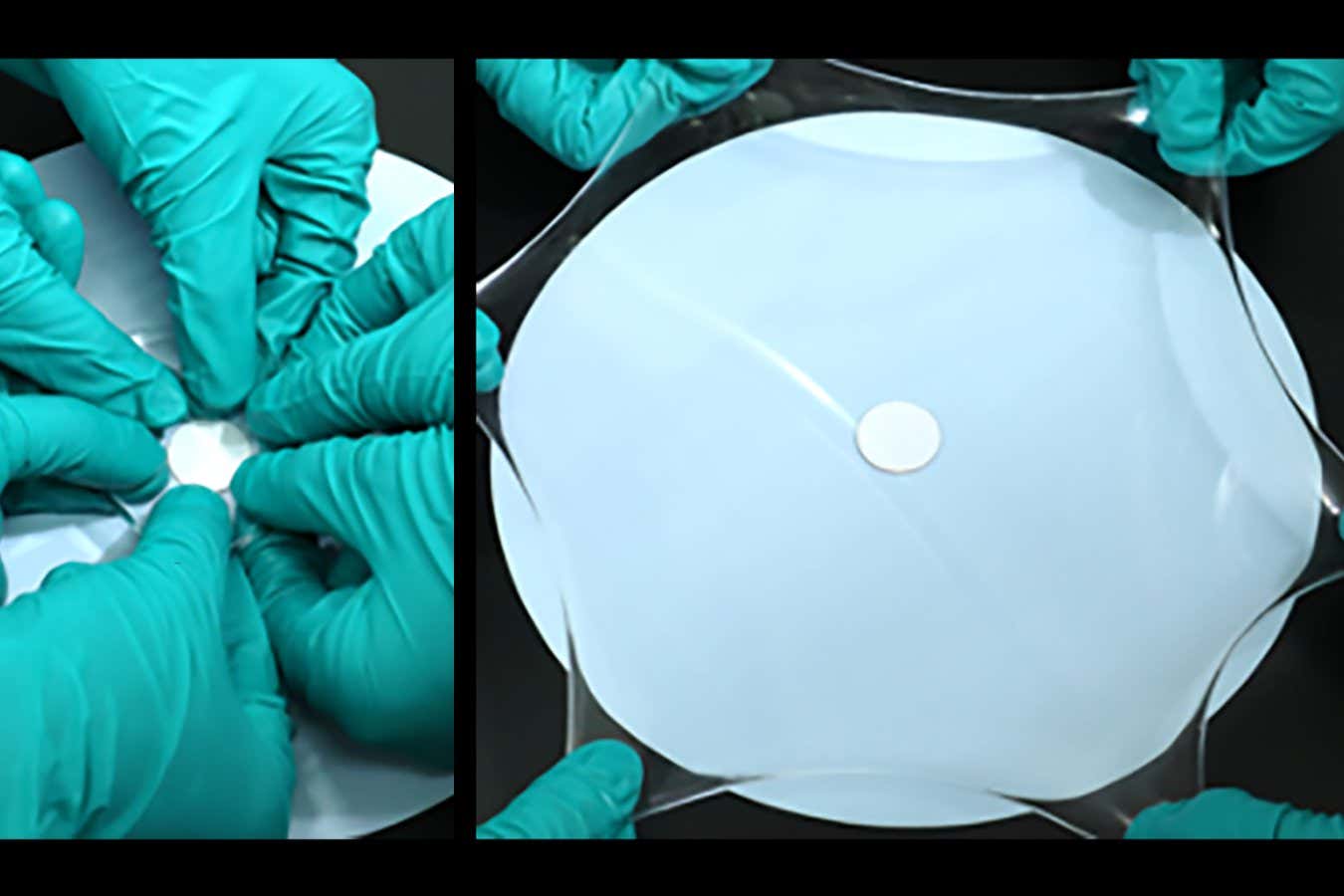

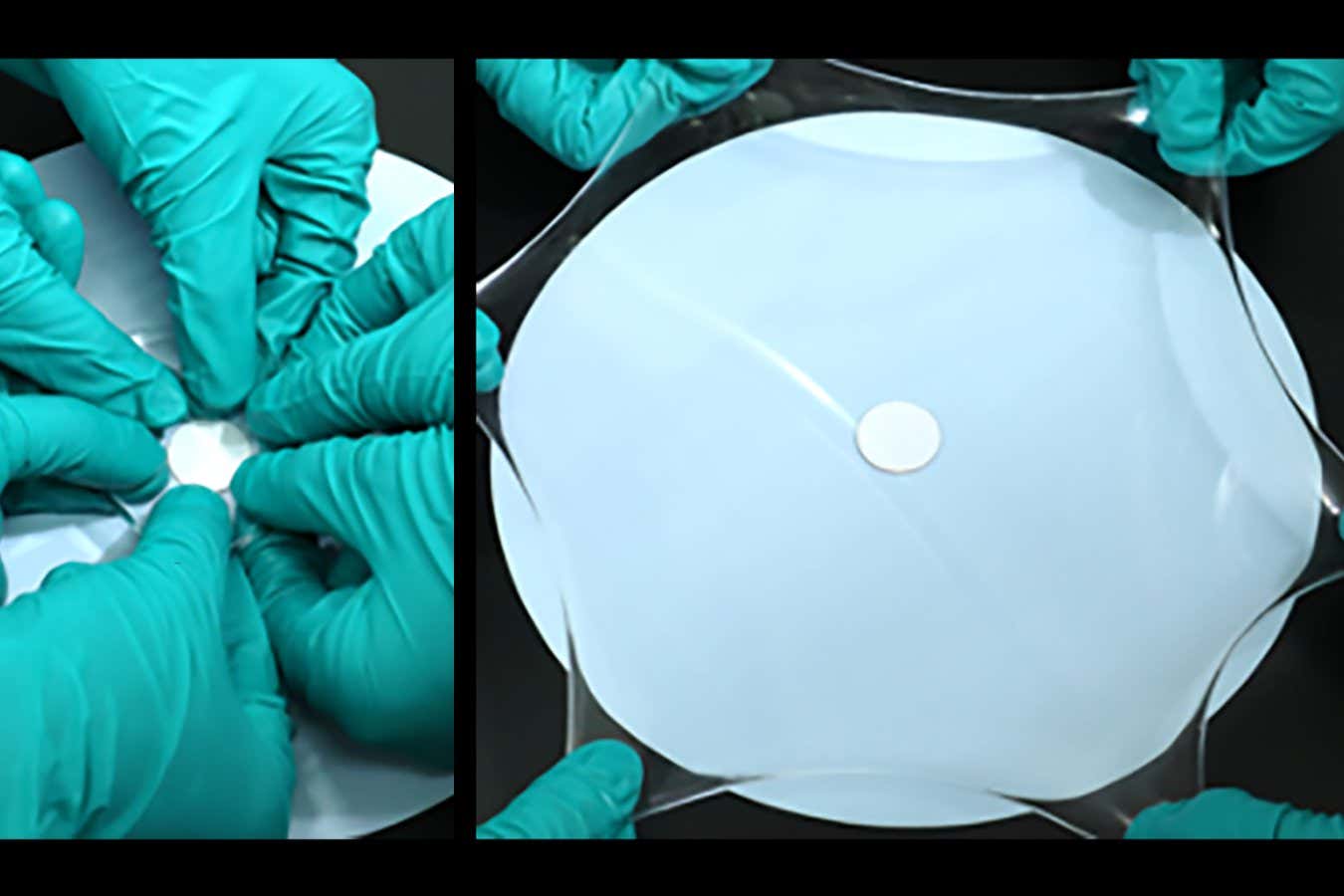

Science & Environment1 month agoHyperelastic gel is one of the stretchiest materials known to science

-

Technology4 weeks ago

Technology4 weeks agoIs sharing your smartphone PIN part of a healthy relationship?

-

Science & Environment1 month ago

Science & Environment1 month ago‘Running of the bulls’ festival crowds move like charged particles

-

Science & Environment1 month ago

Science & Environment1 month agoHow to unsnarl a tangle of threads, according to physics

-

Science & Environment1 month ago

Science & Environment1 month agoMaxwell’s demon charges quantum batteries inside of a quantum computer

-

Technology1 month ago

Technology1 month agoWould-be reality TV contestants ‘not looking real’

-

Science & Environment4 weeks ago

Science & Environment4 weeks agoX-rays reveal half-billion-year-old insect ancestor

-

Science & Environment1 month ago

Science & Environment1 month agoSunlight-trapping device can generate temperatures over 1000°C

-

Science & Environment1 month ago

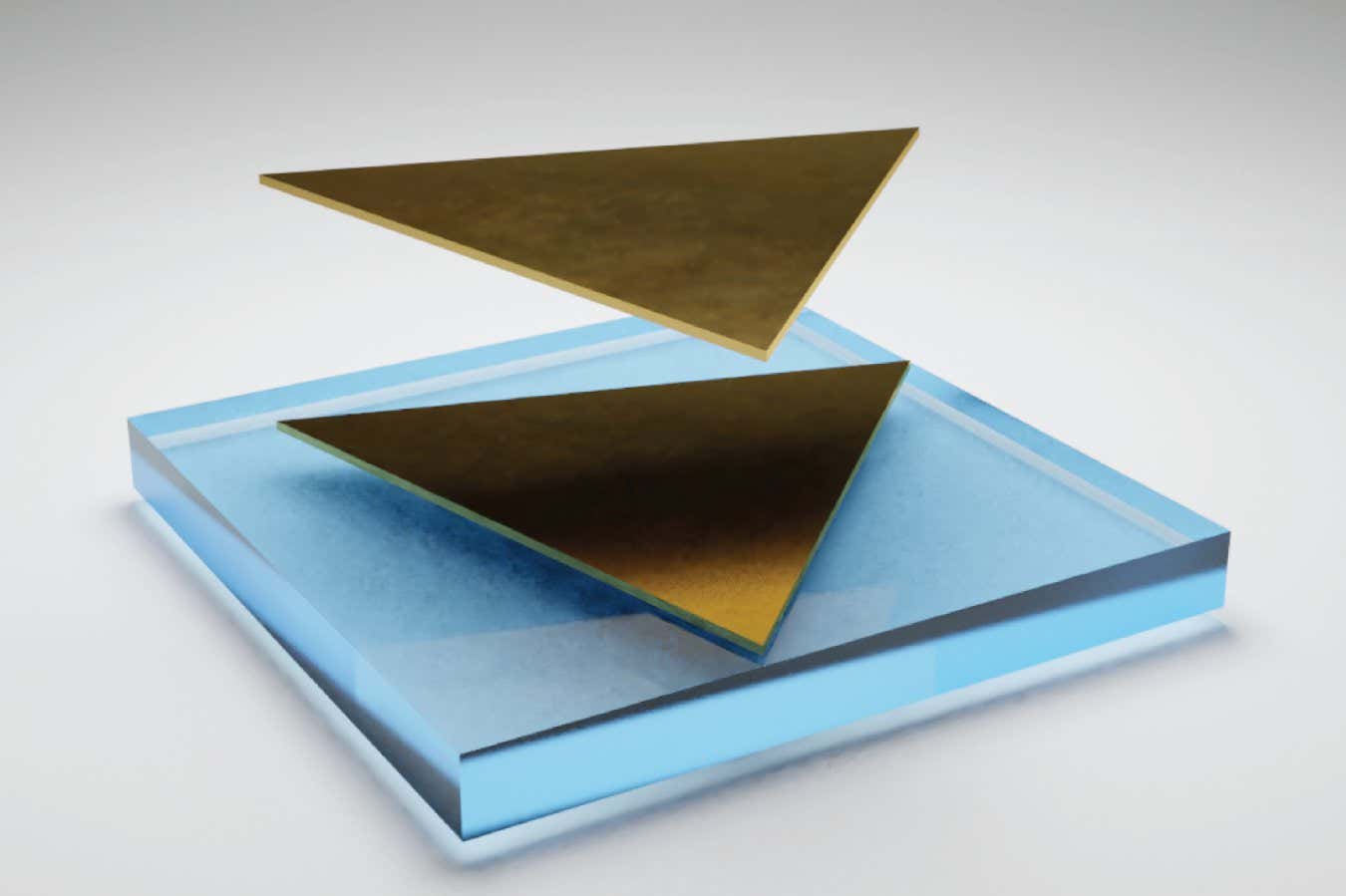

Science & Environment1 month agoLiquid crystals could improve quantum communication devices

-

Science & Environment1 month ago

Science & Environment1 month agoQuantum ‘supersolid’ matter stirred using magnets

-

Womens Workouts4 weeks ago

Womens Workouts4 weeks ago3 Day Full Body Women’s Dumbbell Only Workout

-

Technology3 weeks ago

Technology3 weeks agoUkraine is using AI to manage the removal of Russian landmines

-

TV3 weeks ago

TV3 weeks agoসারাদেশে দিনব্যাপী বৃষ্টির পূর্বাভাস; সমুদ্রবন্দরে ৩ নম্বর সংকেত | Weather Today | Jamuna TV

-

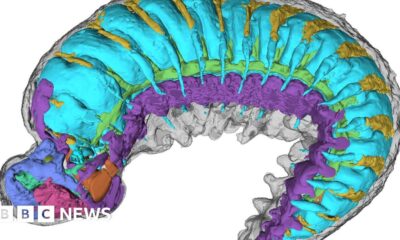

Science & Environment1 month ago

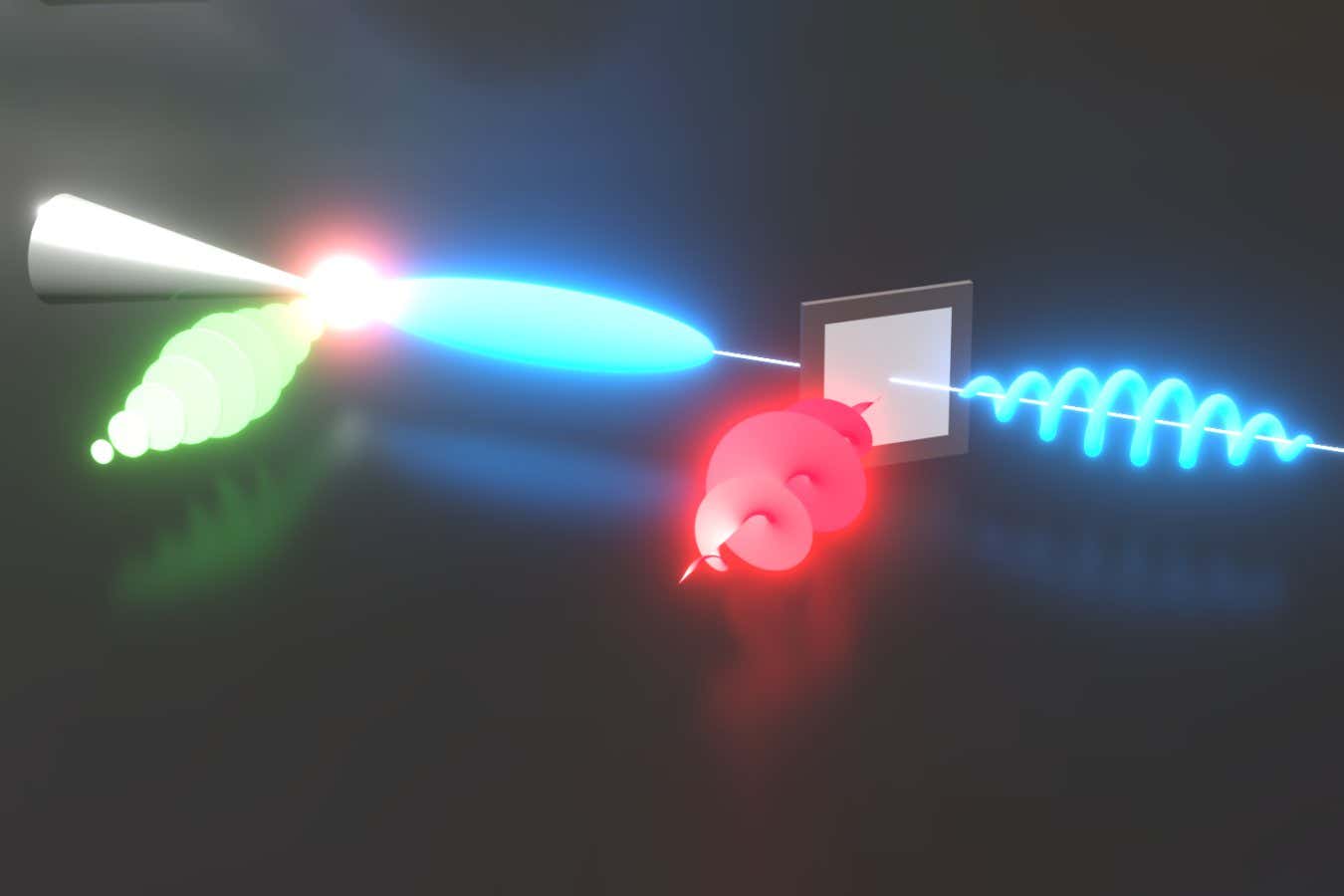

Science & Environment1 month agoLaser helps turn an electron into a coil of mass and charge

-

Science & Environment1 month ago

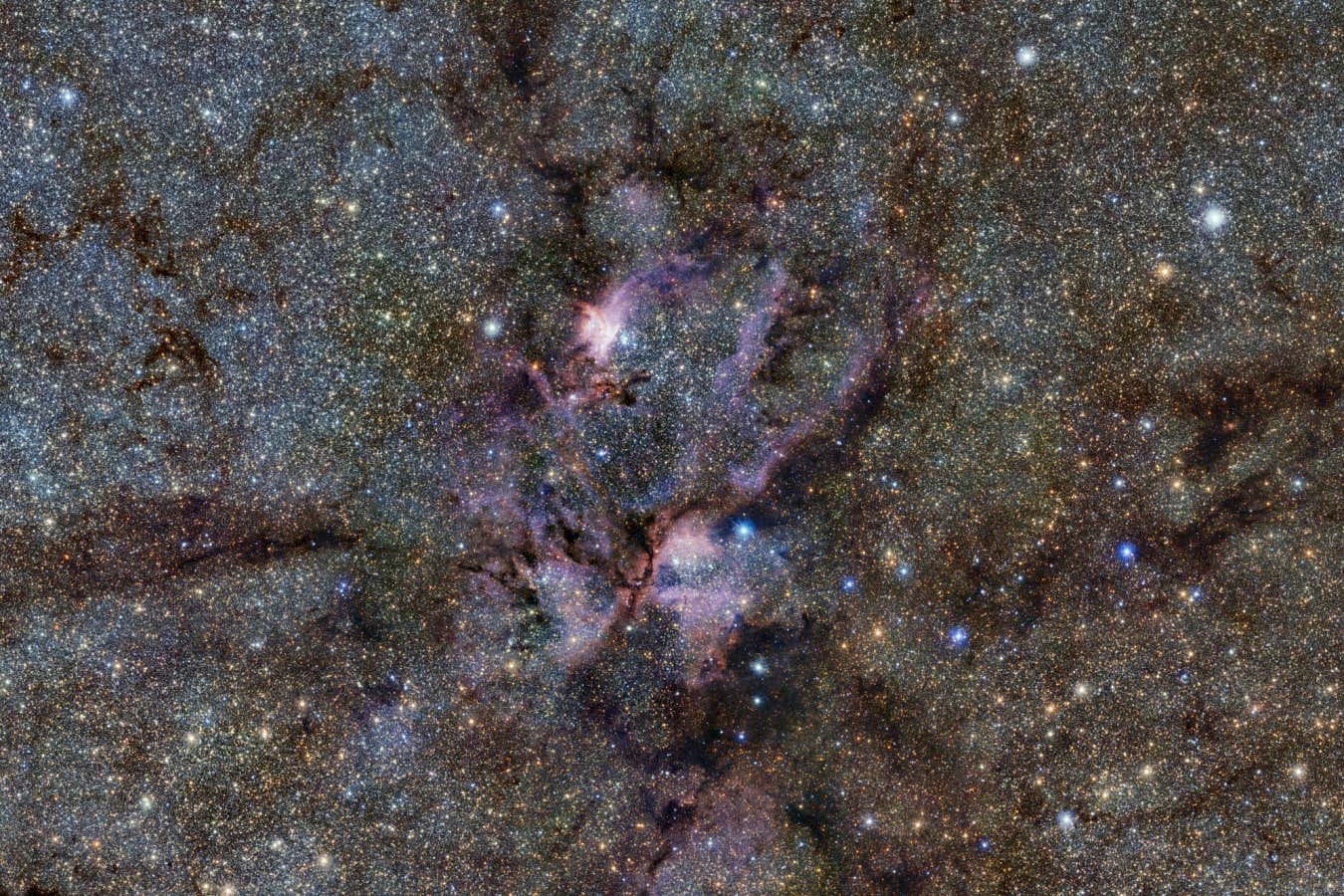

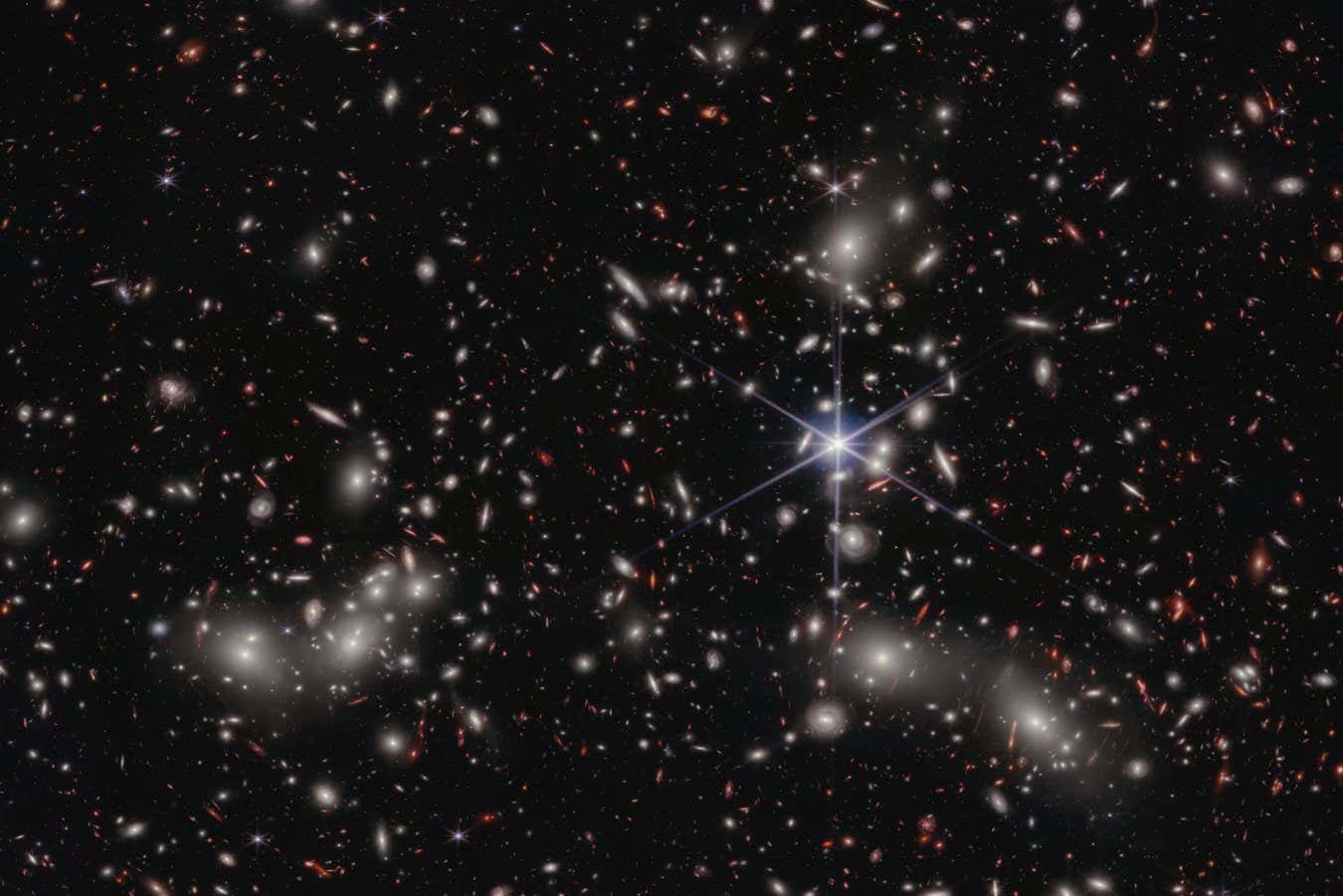

Science & Environment1 month agoWhy this is a golden age for life to thrive across the universe

-

Science & Environment1 month ago

Science & Environment1 month agoA new kind of experiment at the Large Hadron Collider could unravel quantum reality

-

Science & Environment1 month ago

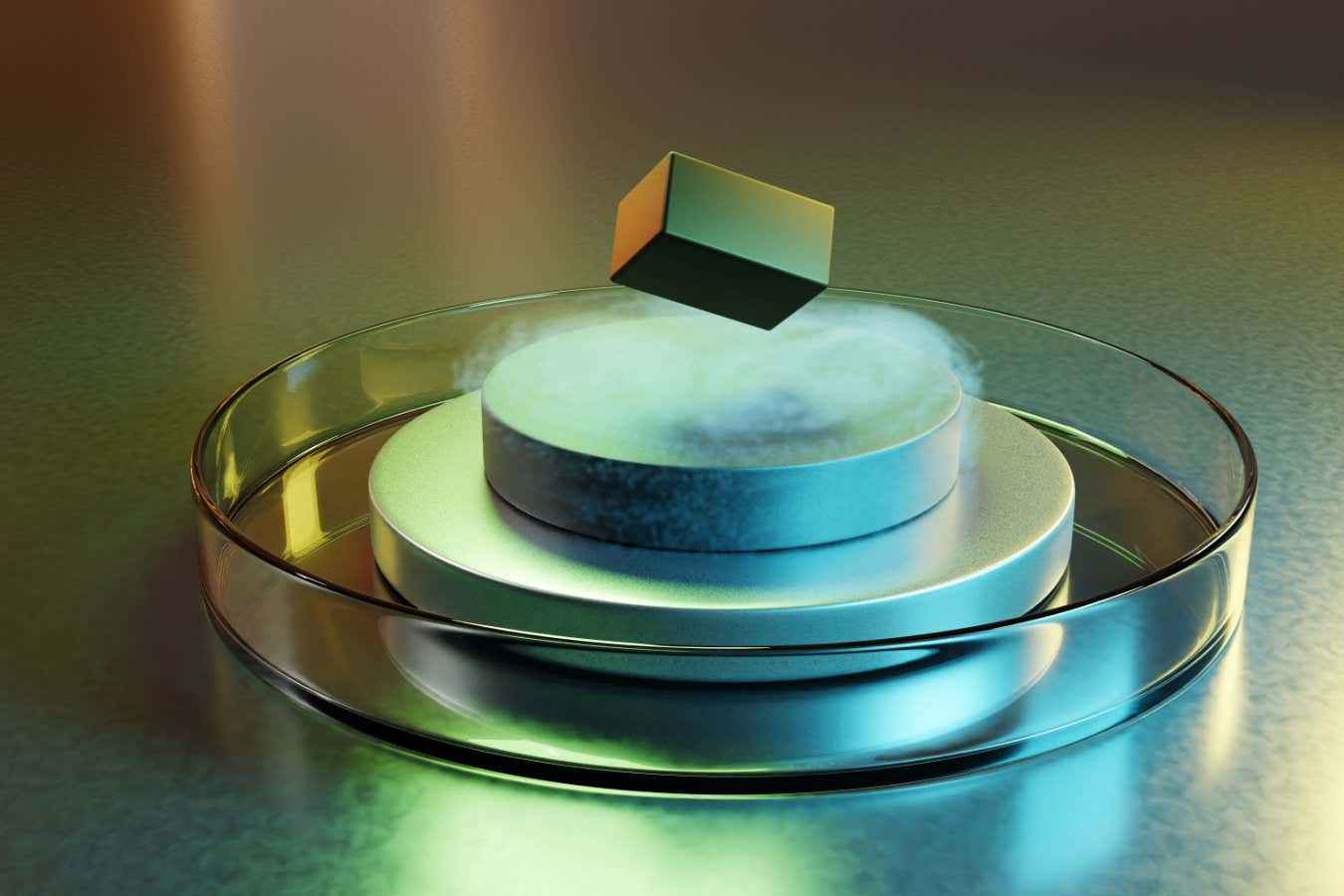

Science & Environment1 month agoQuantum forces used to automatically assemble tiny device

-

Science & Environment1 month ago

Science & Environment1 month agoA slight curve helps rocks make the biggest splash

-

Science & Environment1 month ago

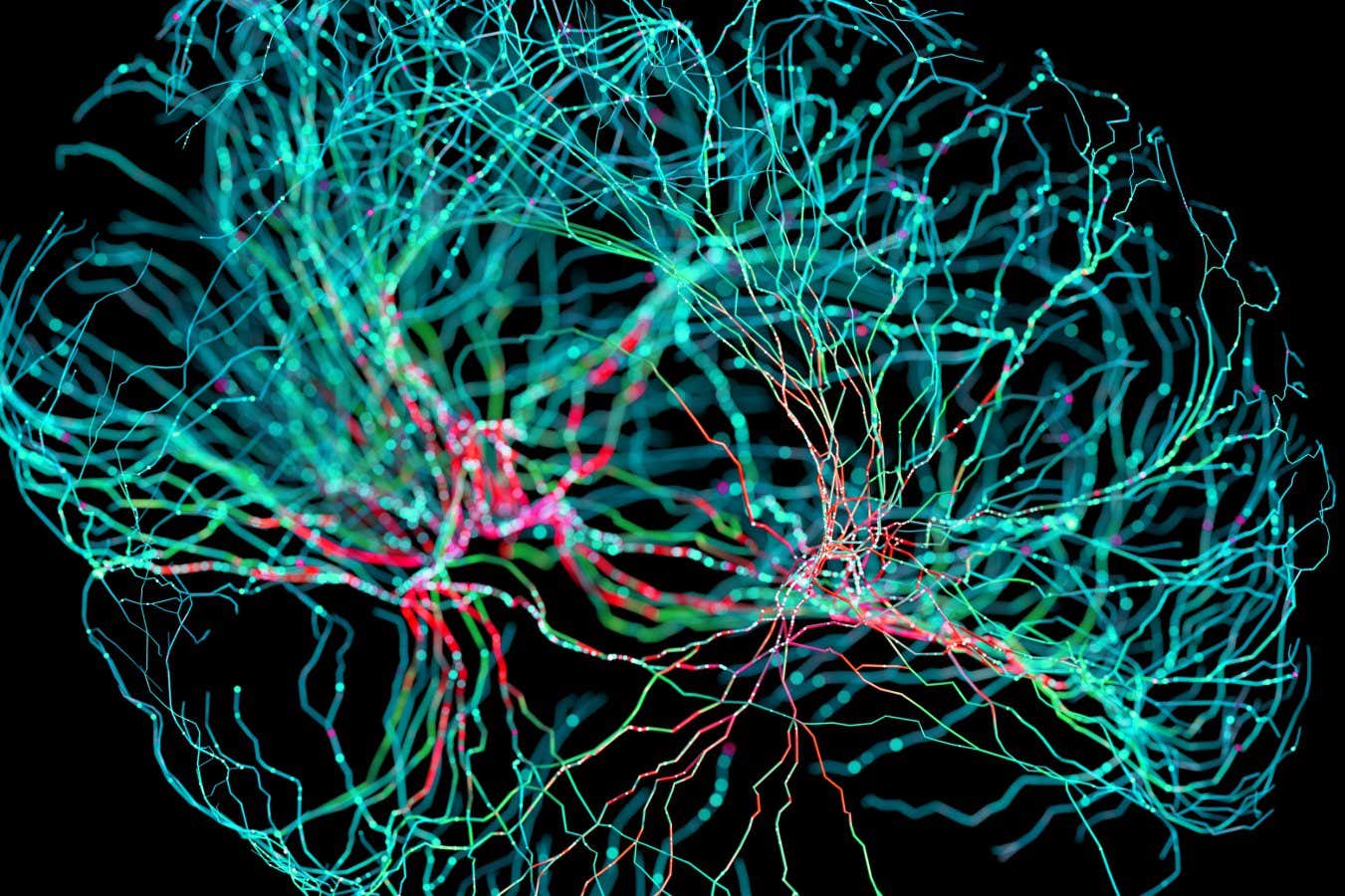

Science & Environment1 month agoNerve fibres in the brain could generate quantum entanglement

-

Science & Environment1 month ago

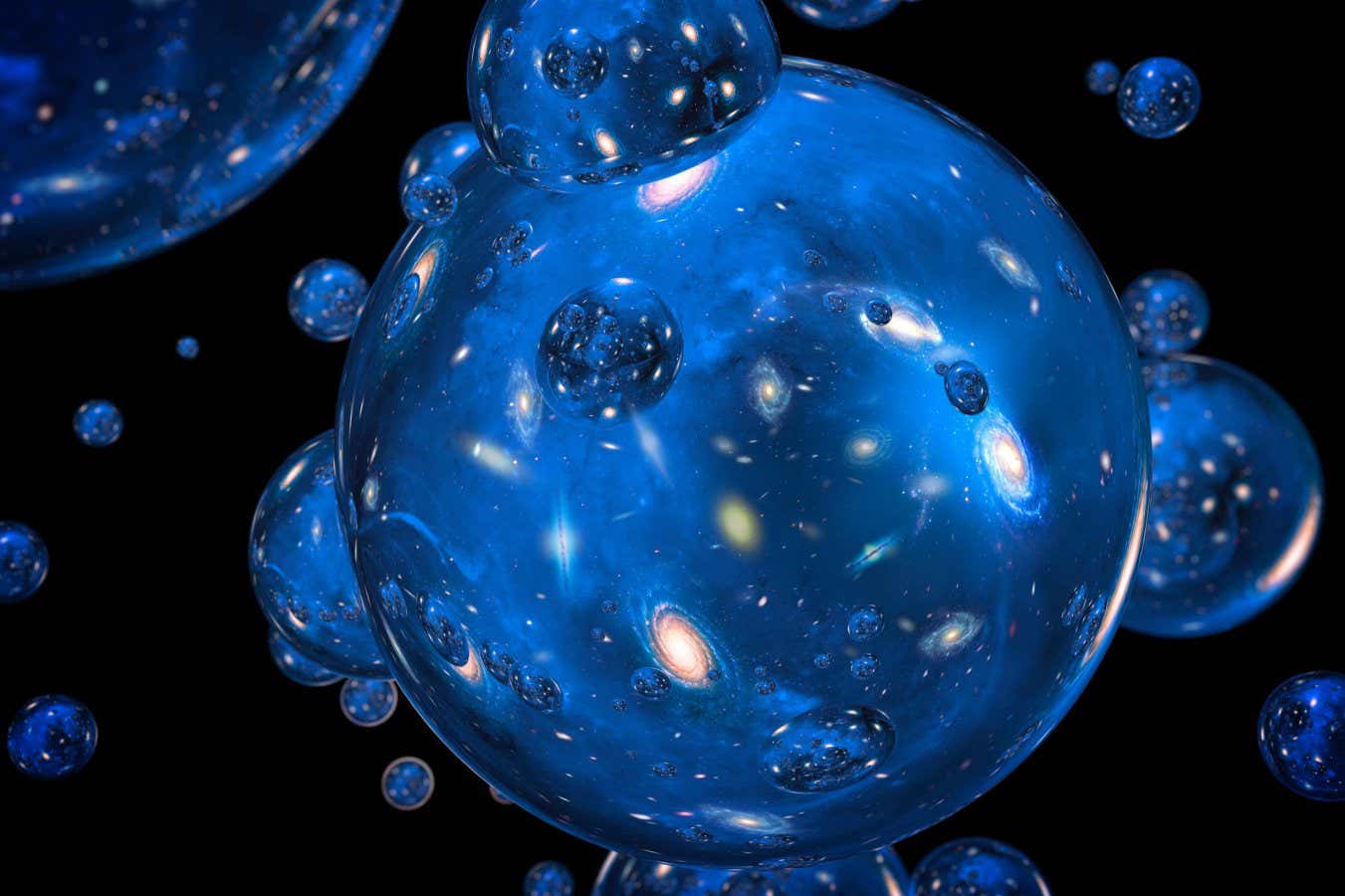

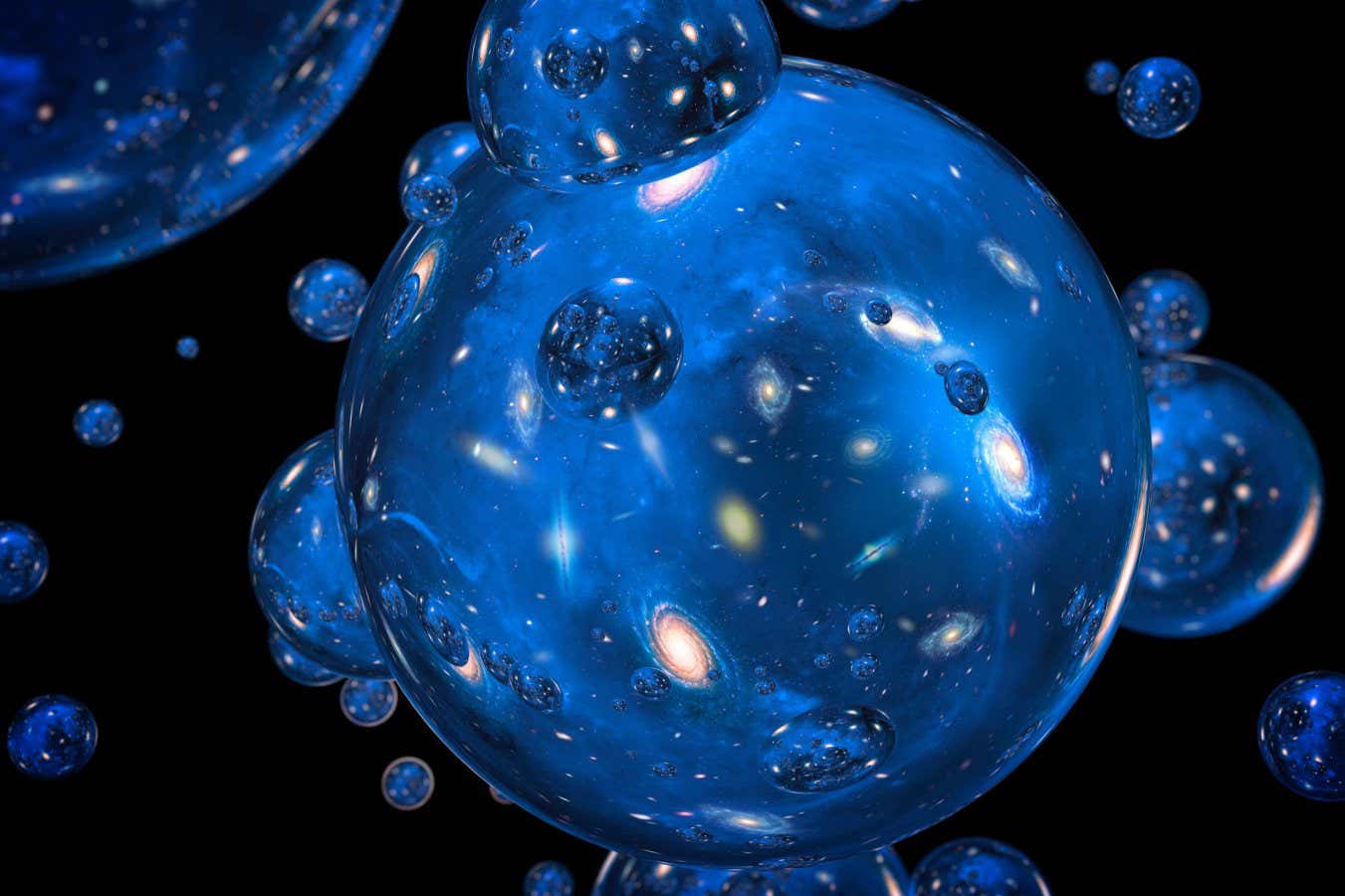

Science & Environment1 month agoHow to wrap your mind around the real multiverse

-

Football3 weeks ago

Football3 weeks agoRangers & Celtic ready for first SWPL derby showdown

-

Business3 weeks ago

DoJ accuses Donald Trump of ‘private criminal effort’ to overturn 2020 election

-

News3 weeks ago

News3 weeks agoMassive blasts in Beirut after renewed Israeli air strikes

-

Business3 weeks ago

Business3 weeks agoWhen to tip and when not to tip

-

News2 weeks ago

News2 weeks agoNavigating the News Void: Opportunities for Revitalization

-

News1 month ago

News1 month ago▶️ Hamas in the West Bank: Rising Support and Deadly Attacks You Might Not Know About

-

Science & Environment1 month ago

Science & Environment1 month agoITER: Is the world’s biggest fusion experiment dead after new delay to 2035?

-

MMA3 weeks ago

MMA3 weeks agoJulianna Peña trashes Raquel Pennington’s behavior as champ

-

News1 month ago

News1 month ago▶️ Media Bias: How They Spin Attack on Hezbollah and Ignore the Reality

-

Science & Environment1 month ago

Science & Environment1 month agoNuclear fusion experiment overcomes two key operating hurdles

-

Science & Environment1 month ago

Science & Environment1 month agoPhysicists have worked out how to melt any material

-

Science & Environment1 month ago

Science & Environment1 month agoTime travel sci-fi novel is a rip-roaringly good thought experiment

-

News1 month ago

the pick of new debut fiction

-

News1 month ago

News1 month agoOur millionaire neighbour blocks us from using public footpath & screams at us in street.. it’s like living in a WARZONE – WordupNews

-

Technology3 weeks ago

Technology3 weeks agoSamsung Passkeys will work with Samsung’s smart home devices

-

News2 weeks ago

News2 weeks ago▶ Hamas Spent $1B on Tunnels Instead of Investing in a Future for Gaza’s People

-

Sport3 weeks ago

Sport3 weeks agoWales fall to second loss of WXV against Italy

-

Technology3 weeks ago

Technology3 weeks agoMicrophone made of atom-thick graphene could be used in smartphones

-

MMA3 weeks ago

MMA3 weeks agoPereira vs. Rountree prediction: Champ chases legend status

-

MMA2 weeks ago

MMA2 weeks ago‘Uncrowned queen’ Kayla Harrison tastes blood, wants UFC title run

-

Sport3 weeks ago

Sport3 weeks agoWorld’s sexiest referee Claudia Romani shows off incredible figure in animal print bikini on South Beach

-

Sport3 weeks ago

Sport3 weeks agoBoxing: World champion Nick Ball set for Liverpool homecoming against Ronny Rios

-

Technology1 month ago

Technology1 month agoMeta has a major opportunity to win the AI hardware race

-

Technology4 weeks ago

Technology4 weeks agoWhy Machines Learn: A clever primer makes sense of what makes AI possible

-

MMA3 weeks ago

MMA3 weeks agoDana White’s Contender Series 74 recap, analysis, winner grades

-

Technology3 weeks ago

Technology3 weeks agoMusk faces SEC questions over X takeover

-

News3 weeks ago

News3 weeks agoFamily plans to honor hurricane victim using logs from fallen tree that killed him

-

Sport2 weeks ago

Sport2 weeks agoCoco Gauff stages superb comeback to reach China Open final

-

Technology3 weeks ago

Technology3 weeks agoThis AI video generator can melt, crush, blow up, or turn anything into cake

-

Sport3 weeks ago

Sport3 weeks agoSturm Graz: How Austrians ended Red Bull’s title dominance

-

MMA2 weeks ago

MMA2 weeks agoPereira vs. Rountree preview show live stream

-

News2 weeks ago

News2 weeks agoHeavy strikes shake Beirut as Israel expands Lebanon campaign

-

TV2 weeks ago

TV2 weeks agoLove Island star sparks feud rumours as one Islander is missing from glam girls’ night

-

News3 weeks ago

News3 weeks agoHeartbreaking end to search as body of influencer, 27, found after yacht party shipwreck on ‘Devil’s Throat’ coastline

-

News3 weeks ago

News3 weeks ago‘Blacks for Trump’ and Pennsylvania progressives play for undecided voters

-

Money3 weeks ago

Money3 weeks agoWetherspoons issues update on closures – see the full list of five still at risk and 26 gone for good

-

Sport3 weeks ago

Sport3 weeks agoMan City ask for Premier League season to be DELAYED as Pep Guardiola escalates fixture pile-up row

-

Business3 weeks ago

Bank of England warns of ‘future stress’ from hedge fund bets against US Treasuries

-

Business3 weeks ago

Business3 weeks agoChancellor Rachel Reeves says she needs to raise £20bn. How might she do it?

-

MMA3 weeks ago

MMA3 weeks agoAlex Pereira faces ‘trap game’ vs. Khalil Rountree

-

Business3 weeks ago

Sterling slides after Bailey says BoE could be ‘a bit more aggressive’ on rates

-

News3 weeks ago

News3 weeks agoGerman Car Company Declares Bankruptcy – 200 Employees Lose Their Jobs

-

Technology3 weeks ago

Technology3 weeks agoTexas is suing TikTok for allegedly violating its new child privacy law

-

Technology3 weeks ago

Technology3 weeks agoThe best budget robot vacuums for 2024

-

Science & Environment1 month ago

Science & Environment1 month agoPhysicists are grappling with their own reproducibility crisis

-

Science & Environment1 month ago

Science & Environment1 month agoA tale of two mysteries: ghostly neutrinos and the proton decay puzzle

-

TV3 weeks ago

TV3 weeks agoPhillip Schofield accidentally sets his camp on FIRE after using emergency radio to Channel 5 crew

-

TV3 weeks ago

TV3 weeks agoMaayavi (මායාවී) | Episode 23 | 02nd October 2024 | Sirasa TV

-

Technology3 weeks ago

Technology3 weeks agoPopular financial newsletter claims Roblox enables child sexual abuse

-

News2 weeks ago

News2 weeks agoBalancing India and China Is the Challenge for Sri Lanka’s Dissanayake

-

Technology3 weeks ago

Technology3 weeks agoApple iPhone 16 Plus vs Samsung Galaxy S24+

-

News3 weeks ago

News3 weeks agoHull KR 10-8 Warrington Wolves – Robins reach first Super League Grand Final

-

MMA3 weeks ago

MMA3 weeks agoUFC 307 preview show: Will Alex Pereira’s wild ride continue, or does Khalil Rountree shock the world?

-

Business3 weeks ago

Head of UK Competition Appeal Tribunal to step down after rebuke for serious misconduct

-

Sport3 weeks ago

Sport3 weeks agoAaron Ramsdale: Southampton goalkeeper left Arsenal for more game time

-

Technology2 weeks ago

Technology2 weeks agoA very underrated horror movie sequel is streaming on Max

-

Technology2 weeks ago

Technology2 weeks agoThe best shows on Max (formerly HBO Max) right now

-

Entertainment3 weeks ago

Entertainment3 weeks ago“Golden owl” treasure hunt launched decades ago may finally have been solved

-

Sport1 month ago

Sport1 month agoJoshua vs Dubois: Chris Eubank Jr says ‘AJ’ could beat Tyson Fury and any other heavyweight in the world

-

Technology4 weeks ago

Technology4 weeks agoArtificial flavours released by cooking aim to improve lab-grown meat

-

Business3 weeks ago

Eurosceptic Andrej Babiš eyes return to power in Czech Republic

-

News1 month ago

News1 month agoYou’re a Hypocrite, And So Am I

-

Science & Environment1 month ago

Science & Environment1 month agoRethinking space and time could let us do away with dark matter

-

Science & Environment1 month ago

Science & Environment1 month agoCaroline Ellison aims to duck prison sentence for role in FTX collapse

-

News1 month ago

The Project Censored Newsletter – May 2024

-

Technology3 weeks ago

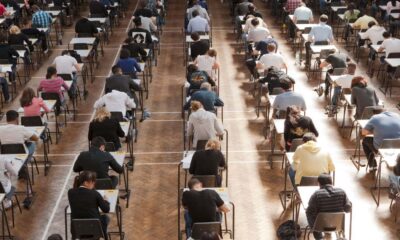

Technology3 weeks agoUniversity examiners fail to spot ChatGPT answers in real-world test

-

Technology3 weeks ago

Technology3 weeks agoEpic Games CEO Tim Sweeney renews blast at ‘gatekeeper’ platform owners

-

Science & Environment3 weeks ago

Science & Environment3 weeks agoMarkets watch for dangers of further escalation

-

Football3 weeks ago

Football3 weeks agoSimo Valakari: New St Johnstone boss says Scotland special in his heart

-

Technology3 weeks ago

Technology3 weeks agoAmazon’s Ring just doubled the price of its alarm monitoring service for grandfathered customers

-

News3 weeks ago

News3 weeks agoWoman who died of cancer ‘was misdiagnosed on phone call with GP’

-

Sport3 weeks ago

Sport3 weeks agoChina Open: Carlos Alcaraz recovers to beat Jannik Sinner in dramatic final

-

MMA3 weeks ago

MMA3 weeks agoKayla Harrison gets involved in nasty war of words with Julianna Pena and Ketlen Vieira

-

Technology3 weeks ago

Technology3 weeks agoUlefone Armor Pad 4 Ultra is now available, at a discount

-

News3 weeks ago

News3 weeks agoReach CEO Jim Mullen: If government advertises with us, we’ll employ more reporters

-

Business3 weeks ago

Maurice Terzini’s insider guide to Sydney

-

Health & fitness3 weeks ago

Health & fitness3 weeks agoNHS surgeon who couldn’t find his scalpel cut patient’s chest open with the penknife he used to slice up his lunch

-

Money3 weeks ago

Money3 weeks agoWhy thousands of pensioners WON’T see State Pension rise by full £460 next year

-

Business3 weeks ago

The search for Japan’s ‘lost’ art

-

Technology3 weeks ago

Technology3 weeks agoHow to disable Google Assistant on your Pixel Watch 3

You must be logged in to post a comment Login